The demands on intralogistics are growing, and with them the expectations placed on connection technology. “Today’s customers no longer want individual cables, connectors, or components, but complete, functioning solutions that fit seamlessly into complex systems. This is changing the tasks of system integrators as well as those of their suppliers,” says Dr. Patrick Olivan, Head of Strategic Business and Industry Development at LAPP, the global market leader for integrated solutions and branded products in the field of cable and connection technology. “To do this, we need to understand the entire application, not just the component.”

Alois Heimler, Industry Manager Intralogistics, adds: “Intralogistics systems are becoming more modular, more varied, and more global. Anyone who wants to remain competitive today must focus on flexible expandability, short installation times, and international standards right from the planning stage.” Instead of simply delivering products, the focus is shifting to the ability to view applications holistically, from engineering and the selection of connection technologies to globally coordinated delivery. This requires a deep understanding of the industry, a broad portfolio, and a willingness to work with customers to develop customized solutions.

From trend to application

With the increasing complexity of intralogistics systems, the requirements for their technical infrastructure are also changing. Different types of machines, controllers, and sensors must work together as a functioning overall system. This integration often takes place under tight time constraints and within the framework of international projects. Every component, every connection, and every interface must fit exactly so that operations run smoothly.

For LAPP, this means that it is not only the quality of individual cables or connectors that is decisive, but also their interaction in specific applications – whether in shuttles, stationary conveyor technology, or driverless transport systems. Electrical, mechanical, and normative requirements must therefore be taken into account as early as the planning phase.

At the same time, users expect global delivery capability and consistently high quality. Connection technology that works reliably in a factory in Germany must also deliver the same performance in an automated plant in the USA or a distribution center in Asia. This requires compliance with country-specific standards and certifications while keeping the number of variants to a minimum.

Eight key applications at a glance

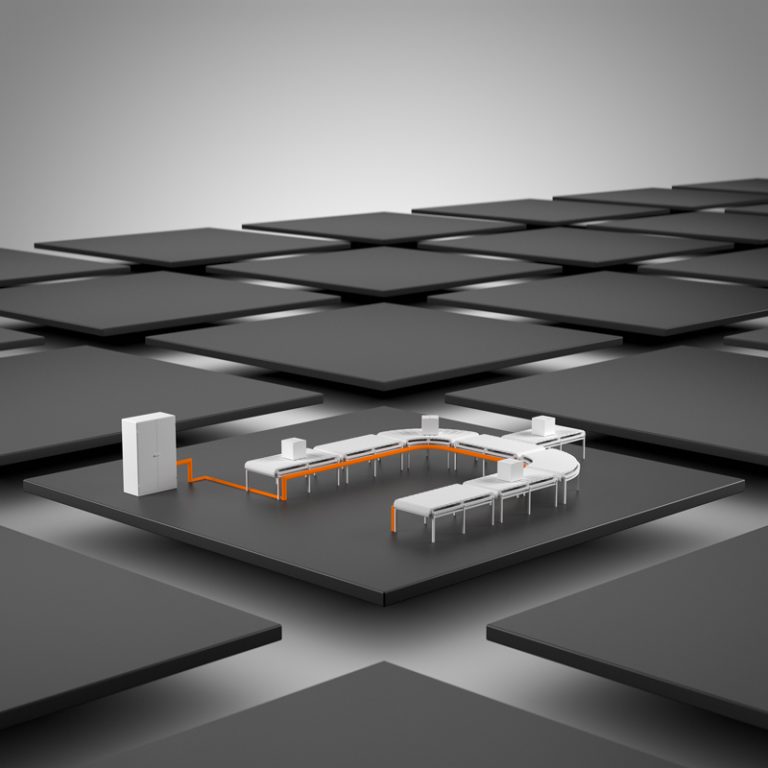

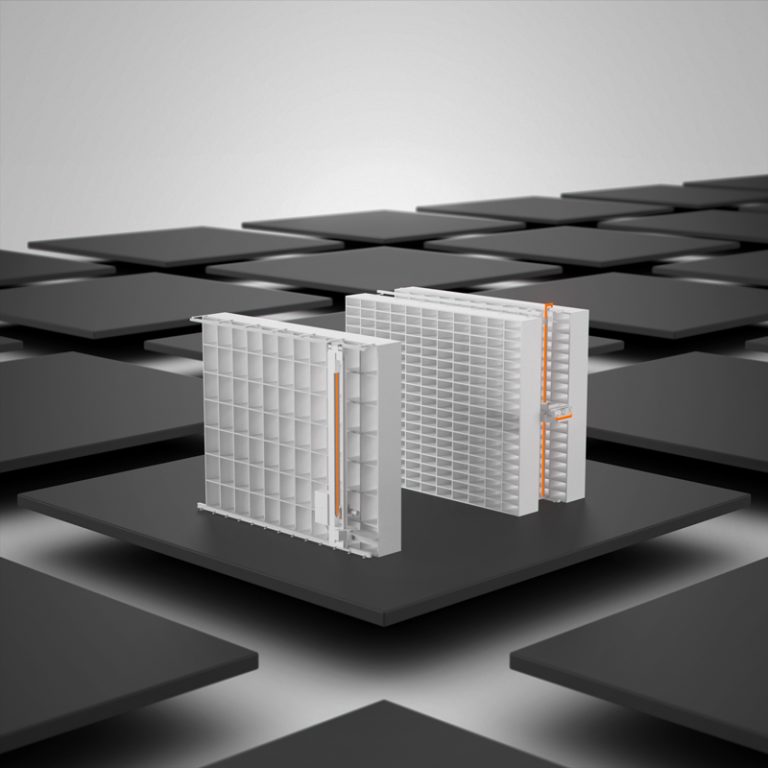

LAPP bundles its expertise in material transport into eight application areas: These include storage and retrieval machines and shuttles as well as rotating rack systems (so-called carousels), classic conveyor technology, and sorting systems. In addition, there are autonomous mobile robots (AMR), the necessary infrastructure cabling from the hall to the machines, and small parts warehouses.

This diversity reflects the different requirements for connection technology in intralogistics and shows how much the application scenarios have changed in recent years: For example, shuttles are increasingly replacing classic storage and retrieval machines in suitable applications. They enable quick access to individual storage locations, which is more important than maximum height or load capacity given the growing proportion of smaller goods sizes. At the same time, operators are relying more heavily on mobile systems: autonomous vehicles such as AMRs or AGVs (automated guided vehicles) move freely around the warehouse and make material flow more flexible than permanently installed conveyor lines.

Processes are also changing in small parts warehouses: Pre-picking is increasingly being integrated into warehouse technology in order to shorten distances and reduce throughput times. For connection technology, this means that less bulk material is required, but more pre-assembled, complex cable sets and interface solutions that are precisely tailored to the respective application.

In the following, three of these application areas show how LAPP is using technological innovation to optimize the efficiency and flexibility of modern intralogistics systems.

Conveyor technology – Less cable, more performance

Conveyor systems form the backbone of many intralogistics systems, and this is precisely where the change is particularly evident. For a long time, centralized cabling concepts dominated: All motors were supplied with power and data cables individually from a control cabinet. This meant large quantities of cable and high installation costs. Today, operators are increasingly relying on decentralized topologies in which frequency converters are located directly on the motors and connected via daisy chain connections. LAPP develops suitable cable systems and pre-assembled connection solutions for these applications, which enable the construction of such decentralized structures. Among other things, patch cords and switches from the ETHERLINE® series, cord sets from the ETHERLINE® and UNITRONIC® series, and remote I/O devices such as the UNITRONIC® ACCESS PN08IOLA08DIO are used. This reduces cable requirements by up to 90 percent and also significantly shortens installation times.

One-cable solutions, which combine power and data transmission in a single connection, also ensure greater efficiency. LAPP develops pre-assembled connection cables that combine connectors, cable glands, and cables. This not only reduces the amount of material used, but also makes planning and maintenance much easier. A project with a leading supplier of material flow systems shows just how great the efficiency gains can be. The initial focus was on reducing costs. Instead of simply optimizing individual components, LAPP redesigned the entire motor connection cable from its own portfolio. The redesign reduced the number of components, simplified installation, and cut overall costs by around 50 percent.

LAPP is currently working with partners on another innovation: a DC microgrid for drives in conveyor technology. The connection with a flat cable is made without tools using piercing technology. This solution significantly shortens assembly times, reduces sources of error during installation, and lowers operating costs over the entire life cycle of a conveyor system.

AMR and modular shuttles – dynamism meets diversity

Autonomous mobile robots (AMR) and modular shuttle systems are shaping the next generation of intralogistics. They offer maximum flexibility, but also place extreme demands on connection technology: minimal installation space, a wide variety of variants, and a lack of standards increase complexity.

An international project with an operator of highly automated warehouses showed how these challenges can be solved. The transport robots used there are among the most compact systems on the market and left only a few millimeters of space for cables and connectors. Standard solutions quickly reach their limits here. Together with the customer’s engineering teams, LAPP developed customized connectors and optimized cable harnesses that fit exactly into the available installation space.

For the latest generation of these robots, the number of design drawings was reduced from 350 to 50 variants, thus reducing the engineering workload. Added to this are the short innovation cycles in which new generations of robots are developed at a rapid pace. LAPP supports this process through continuous revisions every six to twelve months, rapid prototype development, and global coordination of engineering and delivery. This makes LAPP’s connection technologies a key enabler for the scalability and reliability of modern AMRs and shuttles.

Components – tailor-made for every application

Whether it’s a storage and retrieval machine, conveyor system, or mobile robot, every intralogistics system is made up of a large number of individual components. In addition to large applications, performance is therefore determined by the details, such as motors, sensors, cameras, and control systems. This requires robust, standardized, and at the same time flexible connection solutions.

As the global market leader for integrated solutions and branded products in the field of cable and connection technology, LAPP has expanded its range of industrial-grade patch cords. These pre-assembled cables are ready for immediate use, reduce installation time, and simplify maintenance. At the same time, up to 1,200 new connectors have been introduced to the market in the past two years, including robust rectangular connectors and high-performance round connectors from the EPIC® brand. With the recent acquisition of an international manufacturer of industrial connectors, LAPP can now provide solutions worldwide that are specifically tailored to the requirements of intralogistics.

To drive these developments forward at the necessary speed, LAPP has restructured and expanded its engineering department. The results are innovative developments such as the revised HQ series, the expansion of the S/A cordsets portfolio, and the newly designed EPIC® M23 connector, which has multiple patents. The next step is marked by the new EPIC® M12 Push-Pull, which will be presented at this year’s SPS trade fair in Nuremberg and stands for fast, secure connections with noticeable added value.

Competitive advantage through application knowledge

LAPP recognized early on the development in intralogistics from isolated components to integrated solutions and expanded its range accordingly. Today, customers worldwide receive everything from a single source, specially tailored to the industry: from robust, flexible connection components to customized special designs for tight installation spaces to pre-assembled connectors with space-saving designs. This makes LAPP one of the few system providers to cover cables, patch cords, connectors, and accessories with a comprehensive portfolio. In practice, this means high vertical integration, fewer external interfaces, and significant cost advantages through synergy effects.

“We understand the application and deliver the solution,” summarizes Dr. Patrick Olivan. “Our aim is to reduce complexity and make commissioning as easy as possible for our customers.” Alois Heimler emphasizes the long-term approach: “For us, intralogistics is a market in which, in addition to standard offerings, individual requirements are also a priority. We therefore invest specifically in application knowledge in order to continue developing solutions that combine technical excellence with economic efficiency in the future.”

This combination of industry expertise, technological know-how, and international presence makes LAPP a partner that actively helps shape solutions and supports intralogistics on its path to greater efficiency, flexibility, and future-proofing.