The promising catchphrase ‘all-round carefree package’ is used repeatedly in the context of LAPP Harnessing Solutions. What does this phrase mean at LAPP?

“The ‘all-round carefree package’ refers to our range of services, which goes far beyond simple cable assembly or ‘harnessing’. This slogan encompasses a wide range of services: CABLES, SERVO, CHAIN, Box build – and much more. It refers to complete solutions that range from consulting and planning to manufacturing and delivery to ongoing quality assurance. Our goal is to support customers in all phases – from selecting the right products to implementing them in their processes. It starts with consulting and selecting the right cables and components. In doing so, we ensure that the products not only meet the customer’s immediate requirements, but also function optimally for the application. This includes testing, ensuring stable connections, and documenting and providing technical drawings and documents. Basically, we want to provide the customer not just with a product, but with a ready-to-install solution that is tailored to their specific needs and is reliable.”

So, from development to final implementation, you work closely with the customer. Does LAPP also support customers in optimising existing solutions?

“Absolutely! It is often the case that customers already have an idea of the components they need in a harness assembly, but they don’t always make the best choice. Whether in terms of cost efficiency or, for example, stability/robustness. In such cases, we offer our expertise to find the best solution. For example, we can suggest alternative cables or connectors that work better in specific applications – whether because of a smaller bending radius or because they are more robust in dynamic environments. We understand the applications, have a broad overview of our customers’ diverse areas of application, and can therefore provide targeted advice on how to use our components in the best and most cost-effective way.”

Let’s talk about “LAPP Harnessing Solutions”, which is used to describe the assembly service. Why this term, what is behind it?

“The term ‘LAPP Harnessing Solutions’ is actually an international one. Our Harnessing Solutions are not only produced in Germany – we also have a broad presence in EMEA thanks to our various production sites. The teams in the Americas and APAC also have qualified production facilities, of course, which means we can offer our customers a global service if required. We work closely together. At the same time, we have chosen a name that reflects our comprehensive range of services. “Cable assembly” is a familiar term in Germany, but we offer much more than that.

With “Harnessing Solutions,” we signal that we supply complete connection solutions from a single source—from cables and connectors to specific components and more. This makes us unique because we don’t just offer individual products, but entire systems that are optimally coordinated with each other.”

What about production? Do you also cover customised solutions, or does LAPP tend to focus on mass production?

“We serve both. On the one hand, we have efficient production lines that enable us to manufacture large quantities efficiently. On the other hand, we also offer tailor-made, customer-specific solutions in large and small quantities – down to batch size 1. This makes us particularly attractive to medium-sized companies, which often only need smaller quantities. But it also makes us attractive to larger companies, where variety can be a critical factor. It is important for us to be able to respond flexibly to the needs of our customers. In doing so, we ensure that all products, regardless of whether they are produced in large or small quantities, are of the same high quality and that we are seen as a reliable partner.”

LAPP supplies assembly solutions to a wide range of industries, from automation to chemicals. These industries have their own specific requirements. How do you ensure that the products can withstand these demanding environments?

“We have extensive testing facilities and laboratories where our products are tested under extreme conditions. We test for resistance to environmental influences such as salt water, extreme temperatures, or chemical substances. In addition, we have special teams that ensure that our products comply with the norms and standards of the respective industry, for example, in the automotive or food industry.”

Quality is an important topic, but how does LAPP manage to communicate this to the customer? Especially in times when the ‘greed is good’ mentality often prevails and price pressure is high.

“That is indeed a challenge. Our strength lies in the breadth of our offering, from manual manufacturing to highly automated production processes. We can respond flexibly to the needs of our customers, whether in Europe, Asia, or America. Customers recognize the added value when they see that we not only deliver quality, but also adhere to delivery times, ensuring uninterrupted customer supply. Quality is not just a promise, it is also an investment in safety and reliability. This may seem more expensive at first glance or when viewed in isolation, but in the long term or when considering the total cost, it saves money and stress by avoiding production downtime or safety issues.”

‘LAPP Harnessing Solutions combine technical expertise with customised solutions.’

– Michael Seddig, CEO & COO EMEA

What makes LAPP different from its competitors?

“We are globally positioned. Many of our competitors operate primarily locally, which limits their reach. We, on the other hand, offer LAPP Harnessing Solutions worldwide. That is a major advantage we have. Secondly, we are not only a service provider, but also a manufacturer. Many other manufacturers purchase their products, while we manufacture cables and connectors ourselves. This not only allows us to directly influence quality and offer tailor-made, customer-specific solutions, but also gives us manufacturing expertise and in-depth product knowledge that goes beyond the standard. And thirdly, our quality standards are extremely high. This also sets us apart from the competition.”

What role does sustainability play at LAPP? Is there an increasing customer demand for it?

“Sustainability is not only a big and important issue – it is our responsibility. And it will continue to play a major role for us in the future. Many of our customers demand sustainable solutions, and we take this very seriously. We are constantly working to optimize our production processes and materials, whether through the use of recyclable materials or the reduction of raw material consumption in packaging. For example, we use bio-based materials and try to reduce the use of plastics and other environmentally harmful substances. At the same time, we invest in sustainable energy sources at our locations and in particularly energy-efficient systems, among other things. ”

We were talking earlier about the international approach – and this is certainly also linked to growth targets. Are there specific markets that you want to expand with LAPP Harnessing Solutions?

“We have refined our strategy in the Harnessing Solutions division and are expanding markets and partnerships in a targeted manner. This applies, for example, to promising industries such as battery technology. This sector is growing rapidly, especially in connection with the automotive industry, and we are striving to establish a strong position there. But of course, there are also a wide variety of other growth and target markets that we are focusing on. Europe, especially Germany, is and remains an important market for us, where we see further growth potential for LAPP.”

Thank you for the interview!

LAPP Harnessing Solutions in practice

Connection technology plays a crucial role in modern industrial production. With LAPP Harnessing Solutions, the cable and connection technology specialist offers customised and highly specialised solutions that meet the increasing demands of industrial automation and mechanical engineering. LAPP not only supplies high-quality cables and connection technologies, but also acts as a strategic partner in the development and optimisation of connection systems and processes. In the following, we present two practical applications that illustrate the performance and flexibility of these solutions.

From cable harnessing to system solutions

A striking example of the application of LAPP Harnessing Solutions can be found at Sumitomo (SHI) Demag Plastics Machinery, a manufacturer of all-electric injection moulding machines. Since 2017, LAPP has been responsible for the complete assembly of the cable harnesses for the IntElect series for Sumitomo. This series requires precise and reliable cable systems that meet the highest standards in terms of functionality and quality.

LAPP provides the cable harnesses already fully assembled and quality-tested, which significantly reduces the assembly effort on site. These prefabricated cable harnesses ensure an exact fit and can be integrated directly into the machines without additional adjustments. The assembly is carried out in batch size 1, which is particularly advantageous for individual machine adaptations. In addition, direct delivery according to the just-in-time principle enables optimised warehousing and not only reduces the space required, but also the costs for the company.

The collaboration between Sumitomo and LAPP demonstrates the advantages of a partnership model: by outsourcing the cable assembly, Sumitomo can focus its manufacturing capacities on its core business. At the same time, LAPP remains actively involved in the development processes, which means that technological improvements can be implemented more quickly. As a result, several machine variants have already been efficiently equipped with customised cable systems and production time has been reduced.

Customised cable solutions for efficient series production

Another example of LAPP Harnessing Solutions in use is its collaboration with Thomas Technik + Innovation (TTI), a mechanical engineering company. TTI manufactures pultrusion machines that are used to produce fibre-reinforced plastic profiles. These machines have to meet the highest standards of robustness, quality and durability, as they are used in series production.

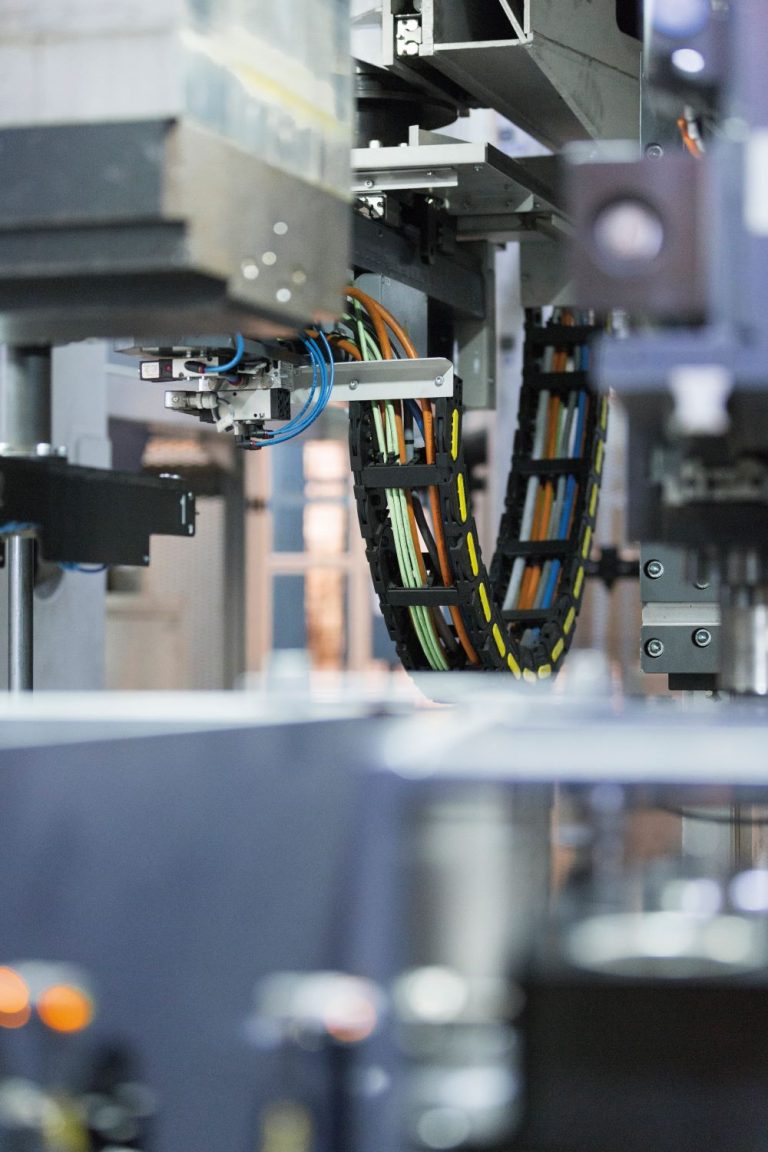

TTI purchases preassembled drag chain systems from LAPP for its latest pultrusion machine, the pullCUBE. The cabling systems, consisting of ÖLFLEX connection and control cables, EPIC industrial plug connectors, SKINTOP cable glands and SILVYN cable protection systems, fulfil the desired criteria that are essential for the operation of the machine.

LAPP’s hybrid cables combine power, control and data lines with other functional elements such as pneumatic or hydraulic lines in a single system. This reduces the space required and minimises the number of necessary interfaces, which increases the reliability and efficiency of the entire machine.

For TTI, the decision to work with LAPP offers significant advantages. The pre-assembled systems enable faster and easier assembly of the pullCUBE, since all cable systems are matched to the specific requirements of the machine and tested. In addition, the high quality of LAPP products helps to reduce maintenance and increase operational reliability.

By integrating these specific cable solutions, TTI was able to optimise the production processes and make the pullCUBE more efficient and powerful. LAPP Harnessing Solutions not only supplies individual components, but also complete system solutions that are precisely tailored to the needs of the machine and its users.

Technological challenges and solutions

These two applications illustrate the specific challenges that modern industrial applications pose for cabling technology. Both customers required precise adaptation of the cable systems to highly dynamic and specialised machine environments. This is where LAPP’s expertise comes into its own, going beyond the mere supply of cables. The technical challenges, such as limited installation space, extreme mechanical loads and the need for reliable signal transmission, are overcome by individually developed system solutions.

LAPP Harnessing Solutions provide customised cabling solutions that save time, guarantee high quality and increase efficiency. Customers can concentrate on their core business while LAPP takes over the complete connection technology – from development to delivery. This not only leads to smooth integration, but also reduces installation effort and lowers process costs, while maintaining the same high quality.