Its beginnings go back a long way: as far back as 10,000 years ago, our ancestors used lime mortar as a binding agent for their structures, and the Egyptians even used burnt lime when building their pyramids. The first records of concrete as we know it today date back to the 18th century. Today, we can no longer imagine doing without the grey construction material used in our road, landscaping and garden construction. Concrete products in all shapes and sizes have been used for many decades in house edgings or private terraces and gardens, as well as in public areas for parks, squares, walking and cycling paths or parking spaces. Presbeton is one of the leading manufacturers of precast concrete parts for both the private and public sector in the Czech Republic. Founded in 1994, the Czech company has been a long-standing customer of LAPP and is constantly working on innovative products and production processes. Over the years, Presbeton has grown to become one of the largest and most respected producers in its industry. The company relies on reliable and long-standing suppliers such as LAPP. As the global market leader for integrated solutions and branded products in the field of cable and connectivity technology, Presbeton in particular values the high level of technical expertise, the good relationship with wholesale supplier SONEPAR, from which Presbeton purchases the goods, and the special design of many LAPP products that is adapted to the environment.

Creating solutions with expert insider knowledge

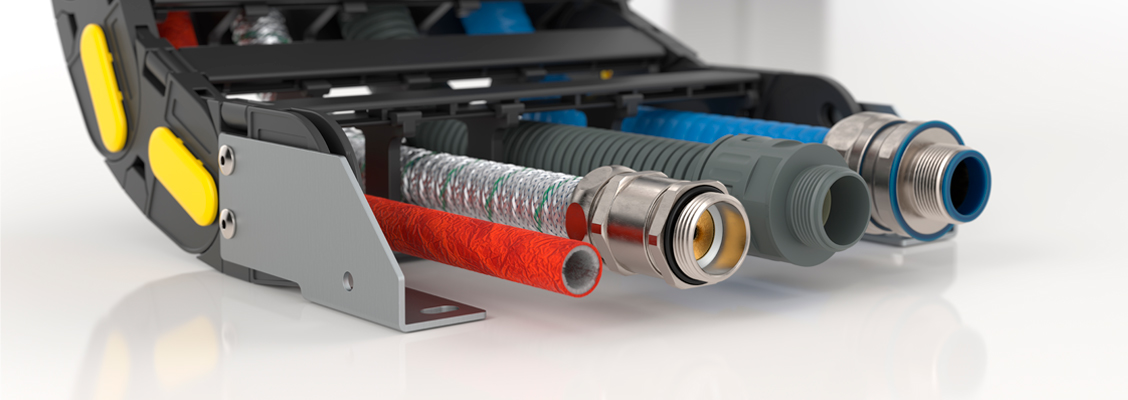

Especially in the demanding environment of Presbeton, LAPP’s expertise and experience are worth their weight in gold: the Czech concrete specialist planned to replace its old cable trolley system in production with a drag chain system from LAPP. The transport system is used in Presbeton’s production to transport the materials used in production. However, frequent downtimes caused by blocked guiding wheels of the old solution caused problems for the manufacturer. After the trolley stopped, the associated safety chain often broke, causing the stationary trolley to pull on the cable and put an excessive strain on it. These were annoying incidents that led to production downtimes. Another major challenge for the LAPP experts is the high level of air humidity and dissolved cement dust in Presbeton’s production, as water is constantly evaporating from the concrete products.

“After discussing all the details with the customer, we suggested a solution with a stainless steel guide rail with a sliding plastic chain for a longer travel distance. This combination ensures long-term and fault-free operation in such a demanding industrial environment”, reports Pavel Vlček, Product Manager at LAPP Czech Republic. In order to find the ideal solution for the long-standing customer, a sales representative from LAPP visited the Presbeton installation on site together with a representative from SONEPAR. Together, the specialists then tested the conditions under which the cable chain should work. Both representatives also looked after the customer during the installation. The team was able to work out the final solution in just three weeks.

Tailored solution for harsh environments

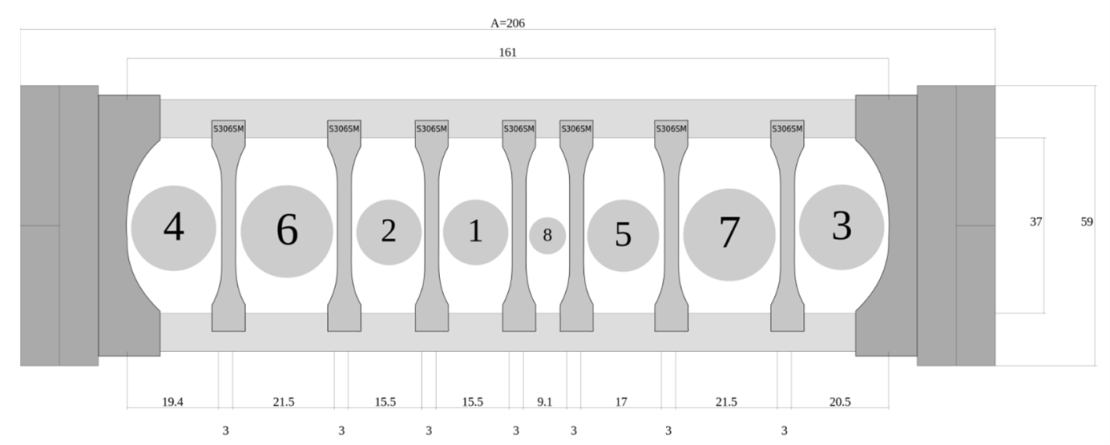

For the internal cabling, the team chose a nylon chain (326SSU161250D) with an inner width of 161 mm and a bending radius of R = 250 mm that is suitable for sliding applications. For a longer travel distance and better stability, a chain has been fitted with a cross section in each link (this is where the letter ‘D’ appears in the chain designation). As standard, this is delivered with a cross section in every second chain link. The cables contained in the cable chain are all specially designed for the demanding environment at Presbeton. The highly flexible power cables for use in harsh operating conditions ÖLFLEX® PETRO FD 865 CP and the ÖLFLEX® FD 855 CP are included on the recommendation of the LAPP specialists. Both cables are also supplemented by the ÖLFLEX® SERVO FD 798 CP, a shielded cable for rotary encoders that is suitable for use in cable chains with high dynamics and demanding conditions, and the ÖLFLEX® ROBUST FD, a halogen-free power and control cable for use in the cable chain, also suitable for demanding environmental conditions.

The design has been working smoothly since the new drag chain solution replaced the old cable trolley system around three quarters of a year ago. This enables Presbeton to fulfil its quality promise to its customers. LAPP continues to supply cables and connectors to the Czech company for the maintenance of the plant.