LAPP cannot predict the future – at least not entirely. What we can do is predict the future of data cables. The key is one of major promises of Smart Factories: predictive maintenance. Data analysis is used to detect defects before they happen so that you can avoid expensive downtime. With Ethernet cables, previous solutions from competitors always required a change to the cable. The new LAPP approach is different. It uses the decreasing transmission capacity of a line to make conclusions about aging and possible failure. The Predictive Maintenance Box can be simply plugged into the Ethernet line.

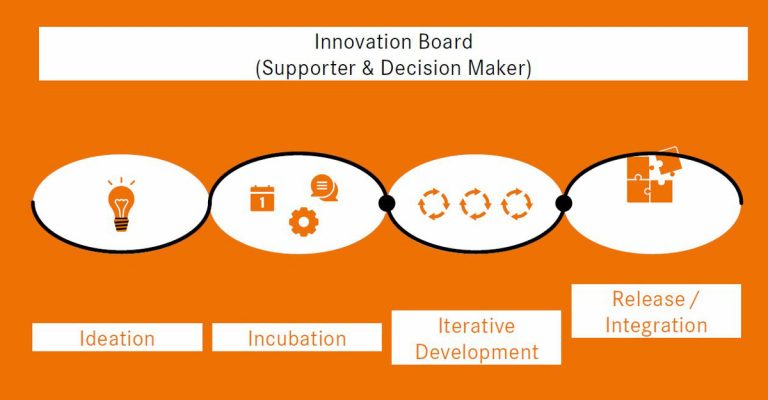

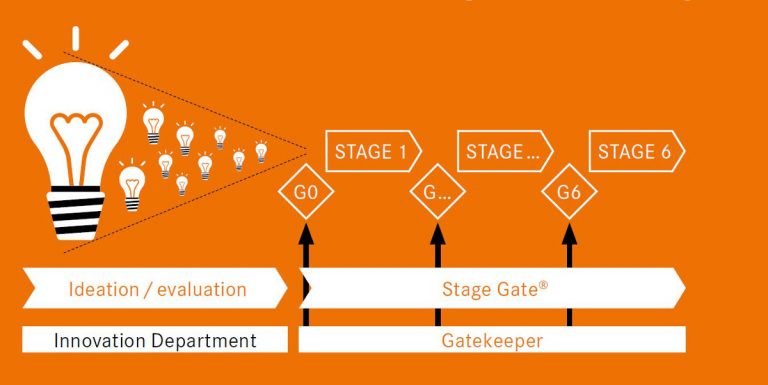

LAPP will soon be entering the pilot phase with three customers from the medical technology, automotive, and intralogistics sectors. This breakthrough in predictive maintenance shows more than LAPP’s capacity to innovate. The company introduced the totally new Innovation for Future process at the beginning of 2019 for complex projects with uncertain outcomes. Generally, it is not intended to replace the usual stage-gate process. The stage-gate process is still the method of choice for incremental innovations, like a new type of cable based on a legacy product. However, when it comes to disruptive solutions and services outside the core business, the Innovation for Future process is the only assurance of success.

Innovative approach to innovation

LAPP’s development of the predictive maintenance solution signaled a different approach to innovation. Due to the technical complexity of innovation, the developers initially focused exclusively on the technology. “For a long time, no one asked themselves which customers could use it and how much they would be willing to pay for it,” explains Guido Ege, the Head of Product Management and Development at LAPP.

In the classic stage-gate process, in which management says yes or no to the continuation of a project at defined intervals, the project would have been quickly concluded without the customer’s involvement. Nevertheless, the response at the Hannover Messe 2019 and the SPS fair showed that the project was headed in the right direction. Customer interest was tremendous. “We now want to further develop this solution with our pilot customers,” says Susanne Krichel, Business Development IoT at LAPP. This case underscores the fact that the topic of innovation also needs to be revaluated and approached in an innovative way.

The transformation of the economy, which is characterized by rapid digitization, new business models and uncertainty about the future, also requires a change in innovation management. With Innovation for Future, LAPP has opened up a space for innovations that would have been unthinkable in the past. “We have defined three requirements for the new process, which must be satisfied at the same time,” explains Georg Stawowy, Member of the Board for Technology and Innovation at LAPP Holding. The innovation team must develop a technical solution, identify the key factors of the business model, and talk to at least one potential customer. The last requirement is especially important for making sure that development does not bypass the customer.

An innovator is someone who creates added value for customers

The customer has always played an important role in LAPP innovations. It is for good reason that, alongside innovation, our customer orientation is anchored in the company’s core values. An innovator is not just someone who pours themselves into the creative process; it’s also someone who creates new added value for the customer. “Our customers do not expect us to constantly reinvent the wheel,” says Innovation Manager Stawowy. The new Innovation for Future process thus fully satisfies the needs of LAPP customers.