A quiet hum accompanies the movements of a production worker as she positions a steel beam above her head – precisely, with concentration, and above all, effortlessly. Her shoulders remain relaxed, her back straight. No strained facial expression, no sign of exhaustion – even though she has been doing this job for hours. She is supported by the active S700 shoulder exoskeleton, which powerfully assists her with every lifting movement and noticeably reduces physical strain. Like a technical extension of her body, the pneumatically operated exoskeleton nestles against her back, allowing her to concentrate fully on her work instead of fighting against her physical limitations.

In view of increasing pressure to innovate and compete, coupled with a growing shortage of skilled workers, the question is becoming increasingly relevant: How can technology help keep people healthy, productive, and motivated in the long term when performing physically demanding tasks? This is exactly where the Industry 5.0 concept comes in: it puts people back at the center—not as cogs in the system, but as active shapers of the industrial working world. Smart technologies are not intended to replace people, but to expand their capabilities and relieve them of strain in the long term.

The active shoulder exoskeleton S700 from exoIQ, part of the TTS Group, which also includes the electronic tool manufacturer Festool, meets this requirement. It combines modern pneumatic technology with intelligent control and an ergonomic fit. This enables physically demanding activities to be performed over a longer period of time without causing physical strain or fatigue. LAPP’s UNITRONIC® FD P Plus is used for reliable transmission of motion data: a highly flexible, abrasion-resistant data cable specially developed for dynamic applications in confined spaces. It ensures that communication between man and machine runs smoothly, every second, with every movement and over millions of bending cycles.

Exoskeleton S700: From research project to viable innovation

The origins of the S700 exoskeleton lie in a research project. Bernward Otten, founder and CEO of exoIQ, developed the underlying concept at Helmut Schmidt University in Hamburg. The aim was to relieve the strain on people in industrial working environments by providing them with a practical tool. In close cooperation with the TTS Group and, in particular, the development teams at its subsidiary Festool, this scientific vision was turned into a market-ready product. The combination of the agile innovative strength of a start-up and the structured processes of an experienced series manufacturer enabled rapid, market-oriented implementation.

The result is the S700: an active shoulder exoskeleton that uses electro-pneumatic technology to support the wearer with additional force of up to five kilograms per arm during overhead work. At the same time, natural freedom of movement is fully retained. Instead of heavy electric motors, pneumatics are used, with compressed air generating movement. This technology offers several advantages: the exoskeleton is both lightweight and powerful, providing gentle, natural force assistance that dynamically adapts to the user’s movement patterns. It is powered by a compact, battery-operated compressor that is integrated into the back unit, making the system completely self-sufficient. Sensors continuously measure the position and movement of the arms. When they detect a need for support, valves in the back direct the compressed air to the drives in both arms, releasing the required force.

For the wearer, this means noticeable physical relief – even during repetitive tasks that last for hours. This significantly reduces the risk of tension and long-term tissue damage in the neck and shoulder muscles, which can occur during heavy overhead work. The S700 is complemented by a Bluetooth-enabled app that records movement data and compressed air supply in real time. The app allows video recording of work activities, performs an ergonomic evaluation of arm movements, and shows how much the S700 supports users in ergonomically critical areas. This allows workplace ergonomics to be continuously optimized. The combination of pneumatics, lightness, and digital ergonomic analysis makes the S700 shoulder exoskeleton a globally unique solution.

Flexible data cable from LAPP ensures movement

The shoulder joint of the S700 combines maximum mobility with minimum installation space. Reliable data transmission is essential at this sensitive point, where the exoskeleton works in sync with the wearer’s movements and undergoes millions of bending cycles. The intelligent control system of the exoskeleton can only respond if the sensors and actuators communicate with each other in real time.

For Stefan Bozler, development engineer at Festool, the movement of the arm actuator presented new challenges. As the person responsible for the control technology of the exoskeleton, he accompanied the project through all development phases – from electronics and software to cable architecture. “In our classic Festool power tools, we hardly need any movable data cables,” explains Bozler. “For the S700, we were looking for a solution that could move flexibly, be installed in tight spaces, and withstand constant mechanical stress.” The high requirements for dynamics, bending radius, and abrasion resistance quickly made it clear that a partner with technological expertise in the field of connection solutions and robotics was needed – LAPP.

LAPP provided the right solution with UNITRONIC® FD P Plus. The highly flexible data cable is specially designed for continuously moving applications and is ideal for use in exoskeletons with multiple cable bends. “Working with LAPP was straightforward and solution-oriented,” says Bozler. “We quickly received the right samples at an early stage of the project and were able to start testing immediately. The cable worked reliably from day one – a component we could rely on throughout the entire development process and which has also proven itself in practice.”

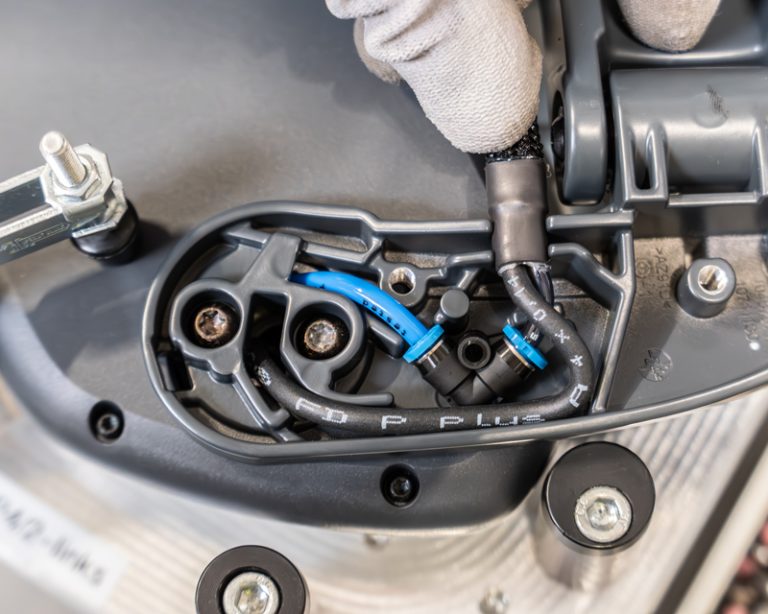

Sebastian Achatz, Business Development Manager ÖLFLEX® Connect at LAPP, supported exoIQ during the development process and summarizes: “The UNITRONIC® data cable has an extremely low bending radius of only 5xd, making it ideal for the confined space in the S700.” The requirements for robustness and durability were also met: “In addition, the highly abrasion-resistant and notch-tough PUR outer sheath offers optimum protection in continuous use,” emphasizes Achatz: “The cable has been tested for ten million movement cycles in our laboratory. This enables us to guarantee high data quality and quantity over the long service life of the exoskeleton.”

Partnership for a people-oriented industry

The UNITRONIC® FD P Plus runs together with a pneumatic hose in a protective fabric hose through the shoulder joint. With a bending radius of 24 millimeters, it forms the technical backbone for control data transmission in the S700 – where maximum movement dynamics prevail in the most confined of spaces. For the exoIQ development team, the collaboration with LAPP, the global market leader for integrated solutions in the field of cable and connection technology, was a relief in a complex development process. “In a project that breaks new technological ground, it was helpful to have a robust, market-proven solution in place for the cabling,” says Bozler.

Bernward Otten comments: “It’s impressive to see how a university research project has turned into an industrial product. In LAPP, we had exactly the right partner whose data cable fits our system perfectly.” The enthusiasm is also palpable at LAPP: “For us, it is something special to be part of an innovation with our UNITRONIC® data cable that literally moves things,” says Achatz. “The S700 stands for ergonomics, for the future, and for a people-friendly industry. And we at LAPP are proud to connect man and machine into a single unit.”