Farmers around the world are under pressure to do more with less: protect crops, safeguard yields, and at the same time cut the use of chemicals that burden both the environment and their budgets. In Australia, where large-scale spraying is a standard part of modern agriculture, this challenge is particularly evident.

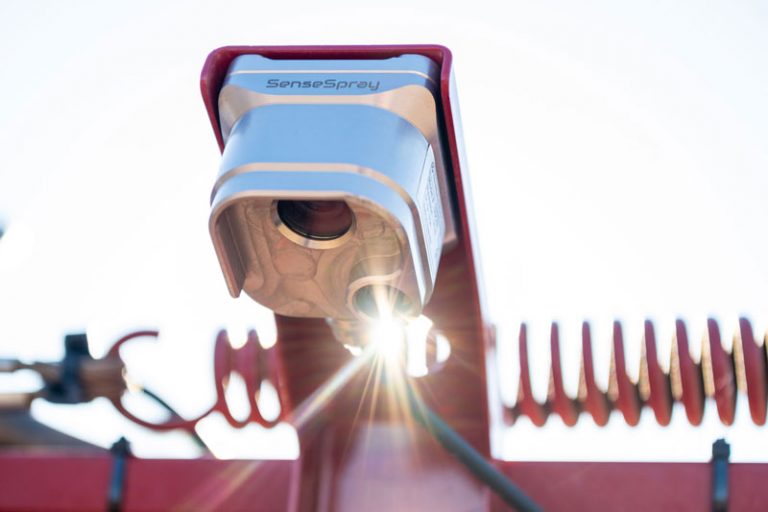

Agtecnic, a specialist in agricultural technology, has developed a solution that tackles this issue head-on. Its SenseSpray® system employs cameras to scan crops in real time, detect weeds, and trigger spray jets only where treatment is required. The result: chemical consumption can be reduced by up to 90 percent without compromising effectiveness. The system can be installed on new sprayers or retrofitted to existing equipment. Typically, it is mounted on boom arms spanning 36 metres, with a camera placed at every metre to capture detailed images of the field.

Such precision farming depends on robust electronic connectivity. Each camera must transmit data and remain fully operational despite dust, moisture, and constant vibration in outdoor use. To meet these demands, Agtecnic relies on complete cable assemblies supplied by the Harnessing Solutions division of LAPP Australia. “SenseSpray is a high-value product, so we needed cables that were high quality, with outstanding durability and reliability in service, which is why we went with LAPP,” said Agtecnic co-founder, Rob Johnson, who, alongside fellow co-founder Peter Roberts, has trusted LAPP products for many years.

Quality technology that pays off

Rob Johnson and Peter Roberts understand investing in advanced spraying technology requires a significant up-front commitment. Yet both are convinced growers will see a rapid payback. The reason is simple: when chemicals are applied only to the weeds that actually threaten the crop, costs for herbicides drop dramatically.

Rob explains how the partnership with LAPP contributed to making SenseSpray® practical and reliable: “We knew the quality of LAPP cables from when we used to buy them individually. LAPP allowed us to buy any type of cable by the metre, with no minimum order quantity, and the majority were stocked here in Australia,” he said.

As the technology matured, the cooperation deepened. “Once they introduced a harnessing solutions division, we were able to leverage off the quality of these cables and create a turnkey service to free up our time even further,” Rob added. For him, one particular service stood out: “Additionally, LAPP is one of the few companies based in Australia that could provide an overmoulding service, which saved us from sourcing this overseas.”

Reliable connectivity solutions built for Australian conditions

With decades of experience in agriculture, Rob Johnson and Peter Roberts understood that no grower will tolerate equipment that fails in the field. Reliability was key to the success of any product in this field.

Rob pointed out the demanding conditions that SenseSpray® must withstand: “The cables that connect these cameras are subject to harsh UV light, water, and generally some of the harshest conditions the Australian climate can produce. We knew LAPP’s cables were up to the task, and they have been performing perfectly in service.”

The role of the cabling extends well beyond the cameras. LAPP assemblies also link solenoids that open and close spray valves with precision. They form the backbone of the CANBUS system, ensuring the entire machine communicates seamlessly. In short, without dependable cabling, the promise of intelligent spraying could not be realized in day-to-day operation.

A partnership for growth

Since its launch about three years ago, SenseSpray® has grown into a technology available across Australia. The company has secured distribution partnerships that bring the system to a wider base of growers and has even begun to establish a presence in overseas markets. For Rob Johnson and Peter Roberts, this momentum confirms that precision spraying meets a genuine need in modern agriculture.

Rob highlighted how the cooperation with LAPP continues to play an important role in scaling the business: “We are always looking at ways to automate agricultural tasks, and we’ve been impressed by the interest in this technology. Now, with LAPP’s Australian-based Harnessing Solutions division, we can get ready-to-go cable assemblies that we know are proven quality, and this saves us even more time.”

What stands out to him is the quality of the relationship as much as the quality of the product: “LAPP has been proactive, responsive, and highly communicative throughout our relationship.” Looking ahead, he sees further opportunities to deepen collaboration: “We are actively looking at ways we can further collaborate, including utilizing their engineering expertise in the product development stage with new innovations.”