In many cases, standard is a concept of the past. A total of 72 percent of those questioned in the management compass, “The Individual Customer 2019”, run by Sopra Steria Consulting and the F.A.Z-Institut, expect products in their industry to be adapted more and more to the individual needs of customers. A specific solution to a specific problem instead of a run-of-the mill offer for the masses – this is also widely used in B2B relationships today. One of the reasons for this is that companies are increasingly relying on highly specialised systems that require equally specialised accessories and components during the course of digitalisation and increasing efficiency. This conviction of being able to offer customised solutions is shared by Officina Meccanica Sestese (OMS Group), a globally active supplier of end-of-the-line packaging solutions based in Paruzzaro, Italy, and LAPP, one of the world’s leading suppliers of intelligent connection solutions. The two companies have a partnership lasting over 20 years, in which LAPP supplies the OMS Group with exactly the right connection solutions for its various machines. LAPP, on the other hand, relies on the solutions from the OMS Group for its packaging system in its new logistics centre in Hanover which were developed to LAPP’s wishes.

Quality, reliability and delivery capability as an indispensable basis for collaboration

Final packaging is an essential factor for safe handling of products and their transport. To meet today’s high productivity requirements, even at the end of the supply chain, corresponding systems must function efficiently, flexibly and precisely and need to be exactly tailored to the respective requirements. The OMS Group offers a comprehensive portfolio of automated strapping, stretch and shrinking hooding as well as shrinking furnaces and

wrapping machine – from individual machines right through to sophisticated complete, ready-to-use packaging systems. According to Maurizio Alessi, Marketing Manager at the OMS Group, for the connection solutions for their machines, only LAPP products come into question for the OMS Group as “the quality and reliability of the LAPP products are the pillars on which our long-term relationship is built.”

Among the solutions selected by the OMS Group, the ÖLFLEX® CONTROL TM power and control cables for fixed installation and the ÖLFLEX® TRAY II power and control cables are particularly noteworthy. Both are UL-listed and have multiple approvals according to NFPA 70/NEC and NFPA 79. For moving machine parts, the OMS Group chooses the flexible ÖLFLEX® CLASSIC FD 810 cables with core insulation and PVC outer sheath. Further solutions are the ÖLFLEX® CLASSIC 110 CY and ÖLFLEX® CLASSIC 100 CY cables for fixed use and the general wiring of machines. The same applies to the ÖLFLEX® SERVO FD 781 CY servo motor cables, which, due to their low capacities, enable longer distances between the converter and the drive. Ultimately, the OMS Group relies on UNITRONIC® cables for data transmission, which are suitable for both fixed and mobile installation.

In addition to the quality of the products, in the opinion of the OMS Group’s packaging specialists, a great deal more speaks in favour of LAPP: “The simple and fast global availability represents one of the main advantages for us as an international group, along with the wide range of UL and CSA certified products for the North American market”.

The “dream machine” for the logistics centre in Hanover

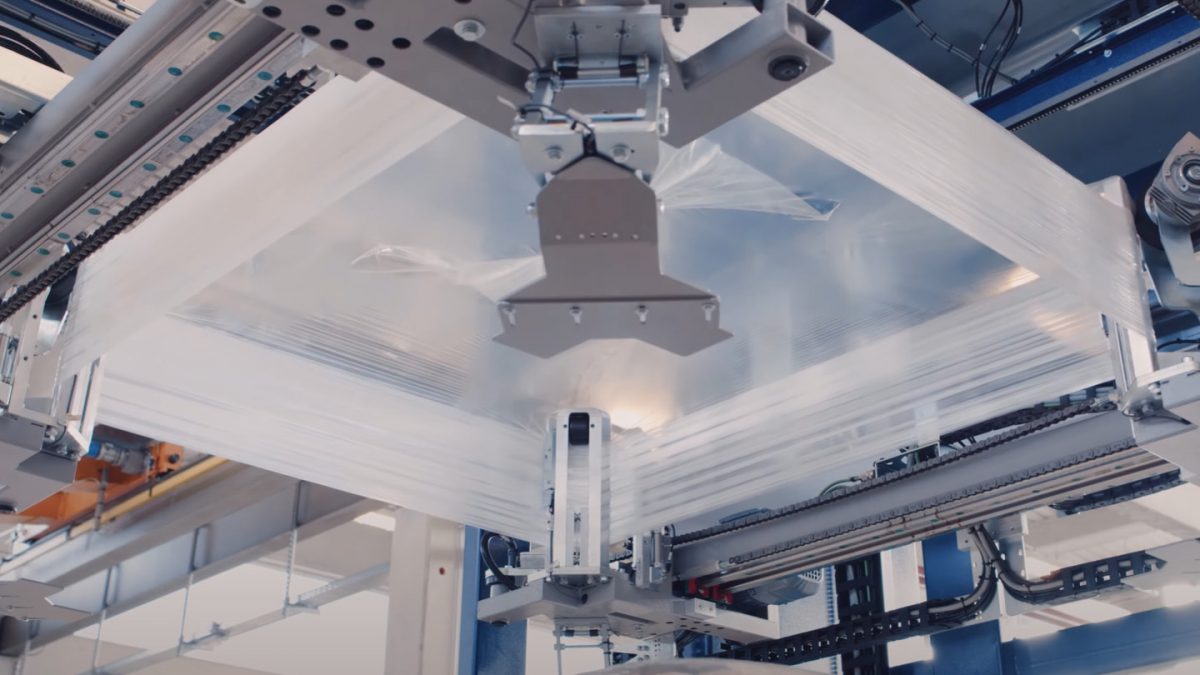

“LAPP and the OMS Group are two international companies, both of which offer added value in developing customised solutions,” emphasises Gaetano Grasso, Head of Product Management and Marketing at LAPP. “This is also why LAPP Germany relied on the high standards of the OMS Group’s tailored offers when choosing the ideal supplier for the new logistics centre in Hanover.” In the course of this, OMS-IPS, German branch of the OMS Group configured the “dream machine” for the logistics site, says Gaetano Grasso. It combines both the strapping and packaging processes in a single workstation using shrink film.

“This enables us to reduce the amount of film as much as possible,” says Andreas Gesse, Head of Logistics Centrein Hanover at LAPP Deutschland. “This solution allows us to pack products with a diameter of up to 120 cm, at a speed of 80 packages per hour. This is twice as much as the machines previously used.” The new logistics centre with a storage area of approx. 15,500 m² indoors and 28,000 m² outdoors opened its doors in October 2020 – in the middle of the Covid-19 pandemic. “In light of this delicate historical period, we all the more appreciate the fact that the OMS Group has strictly adhered to delivery times,” emphasised Andreas Gesse. “This level of customer focus is a key factor in our long-term cooperation – this aspiration in itself has always united LAPP and the OMS Group.”

Video: © OMS Group – Packaging Solutions. Since 1949