There is no future in energy supply based on fossil fuels. If we are to halt climate change, we need to rapidly expand renewable energy – especially photovoltaics. It is estimated that Germany will need 450 gigawatts of peak power by 2050, 300 gigawatts of which will be installed on buildings. There is plenty of space – and not just on roofs. Around 11,700 square kilometers are available on facades, about half of which is on non-residential buildings. According to the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, Germany, 440 gigawatts of PV power could be installed there – far more than is needed for the energy turnaround. The PV components could also perform additional functions such as thermal insulation, wind and weather protection. This huge potential has remained largely untapped because installation is too complex and expensive.

Wiring in seconds

The research project ‘Standard BIPV system – development of standardised BIPV components with integrated system technology’ (funding reference 03EE1061A) aims to solve this problem. BIPV stands for building-integrated photovoltaics. Like its predecessor project Standard-BIPV (funding reference 0324063A-H), it is funded by the Federal Ministry of Economics and Climate Protection (BMWK). In this first project, which will run from 2017 to 2020, the partners, led by Fraunhofer ISE, have developed solutions for attaching PV modules to a facade in a few simple steps and without specialist knowledge. A key component is the connector developed by LAPP. The connector on the PV module is pressed into the counterpart on the supporting structure like two Lego bricks. The module is mechanically and electrically permanently connected in seconds. There is no need for subsequent wiring, saving time and eliminating errors.

As part of the Standard BIPV System project, which runs until January 2024, LAPP is developing the connector to fit most PV modules. LAPP is working closely with the research and development centre of GiB Gesellschaft für innovative Bautechnologie mbH in Arnstorf, Germany. The system integrator knows exactly what is required when mounting the modules on a facade.

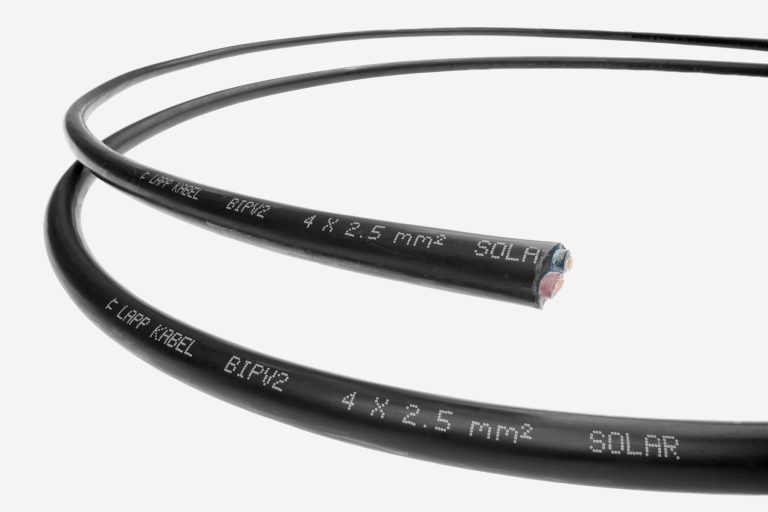

In the project, LAPP is also using a new ÖLFLEX® solar cable developed by LAPP Korea specifically for solar facades. It combines four cores in one thin jacket. In the first project, 24 cables had to be pulled into the house to the inverter for six modules, but now only six of the new cables are needed. The connectors on the cabling side have been redesigned so that instead of four cables, each is connected to just one of the new solar cables. This makes cabling in the support frame easier and requires fewer openings in the wall. There are also plans to integrate micro-inverters on the module frames instead of converting the DC and AC power in large inverters in the building. “The new ÖLFLEX® solar cable is not yet a product. The concept will be finalized shortly and it is planned to get ready for series production soon,” says Werner Körner, Head of Development and Technology at LAPP.

Plug-in principle for roof tiles

Meanwhile, LAPP is already working on a third project called Baldachin, which is also funded by the Federal Ministry for Economic Affairs and Climate Protection (BMWK). The project is entitled “Development of an innovative solar roof element – cost-effective, attractive and easy to install” (funding code: 03EE1115A). The company is developing a connector for easy installation of photovoltaic roof tiles. The solution should enable roofers to install the solar tiles on the roof without tools or specialist knowledge. This would have enormous potential for the expansion of renewable energy: around half of all roofs in Europe have a slope of more than seven per cent, many of which are covered with clay or concrete tiles and are therefore suitable for such solar tiles.

With the Baldachin project and the universal façade connection system currently being developed in the Standard BIPV System project, LAPP is working on practical solutions to make buildings a source of renewable energy. Werner Körner: “In this way, LAPP is making an important contribution to the energy revolution”.