Anyone driving through the tranquil village of Preith in the Bavarian district of Eichstätt would hardly suspect that this is the location of a high-tech company whose innovative strength supports international research institutions. But this is precisely where regineering develops highly specialized environmental simulation systems and individually designed laboratories for universities, research centers, and scientific institutes around the world. Almost every system is unique, tailored precisely to the specific scientific question at hand.

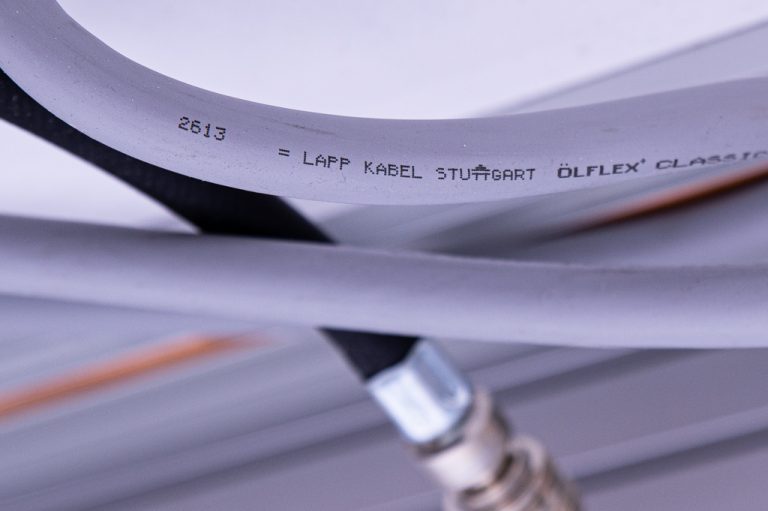

The technological requirements are correspondingly high: for the simulations, the materials and components must withstand extreme cold and heat, strong radiation, and chemical exposure over many years. Since the company’s inception, regineering has relied on connectivity solutions from LAPP. The global market leader for integrated solutions and branded products in the field of cable and connectivity technology contributes significantly to the success of these highly complex systems with its broad portfolio, high-quality connection components, and fast availability. “The first cable I ever used was from LAPP,” recalls Stefan Innerhofer, founder and managing director of regineering. “Since then, our collaboration has grown steadily.”

From campus gas station to high-tech laboratory

The story of regineering begins at the Technical University of Munich. While studying mechanical engineering there, Stefan Innerhofer tinkered with a more environmentally friendly alternative to conventional fuel and converted his car to run on vegetable oil. Since there was no suitable gas station for this, he quickly built his own gas pump right on campus in Garching. This idea became the starting point for an entrepreneurial journey that quickly gained momentum. “I never actually wanted to be an entrepreneur, I just wanted to solve a problem,” says Stefan Innerhofer. “But suddenly people were lining up to fill up at our station. That’s when I realized that a technical idea could also become a business model.”

Innerhofer built his first test benches to test engines converted to run on vegetable oil. Initially, he used them himself, but later orders followed for vegetable oil tractors, among other things. As demand grew, the range of services expanded to include environmental simulation systems and complex research laboratories. In 2012, Stefan Innerhofer founded regineering GmbH, which now also acts as a general contractor with over 100 employees, realizing sophisticated and customized high-tech research buildings.

Environmental simulation under extreme conditions

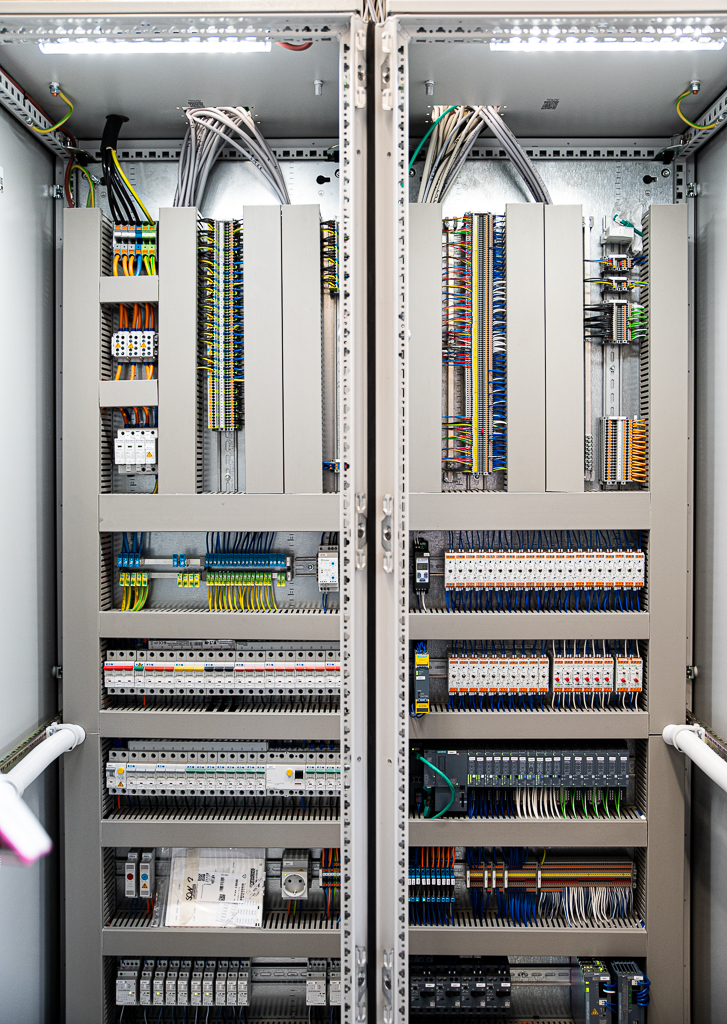

For regineering, environmental simulations involve more than just controlling temperature or humidity. The climate chambers developed and built in Preith must guarantee maximum precision and reliability under extreme conditions. Inside, temperatures range from minus 70 to plus 120 degrees Celsius, humidity from 10 to 95 percent, and gas exposure with ozone, methane, or CO₂. High-voltage tests are also possible in some cases.

A current project for a leading German research center shows just how complex such requirements can be in practice: regineering designed 17 customized climate chambers for this project, most of which are equipped with special lighting systems for plant experiments. “Each chamber is unique. We develop them to be precisely tailored to the respective research question,” explains Lukas Braun, authorized signatory and head of the electronics department. ” , for example, we can simulate how plants might react to changing climatic conditions in 100 years. Our technology provides the answers.”

Another project took the team across the Atlantic: regineering developed special climate chamber for the University of Idaho in which entire plant ecosystems can be researched under controlled conditions. Forest fires are also simulated in order to investigate their long-term effects on the earth. The systems had to be designed in such a way that they could reliably supply thousands of sensors with power and data even under conditions of heat, smoke, and ash.

Such requirements pose enormous challenges for the connection technology used, which go far beyond the standard. “In some projects, cables have to withstand temperature fluctuations of over 190 degrees—from freezing cold to steaming heat,” says Lukas Braun. “At the same time, they must be flexible, shielded, and durable. That’s why we deliberately rely on high-quality components from LAPP.”

Reliable connections in special plant engineering

For regineering, LAPP is much more than just a supplier: the Stuttgart-based family business is a reliable partner when it comes to finding precise and fast solutions for complex requirements. Especially in special plant engineering, where every application has its own specific technical requirements, one thing counts above all else: a comprehensive product portfolio that covers a wide range of applications and a partner who can provide everything from a single source.

“At LAPP, we always find exactly the cable we need,” says Lukas Braun. “Whether shielded, flexible, high-temperature-resistant, or with a high number of cores—we don’t have to search long, we know we’ll find what we’re looking for.” The broad portfolio gives regineering the flexibility it needs to implement individually developed solutions quickly and without technical compromises. This is why connection solutions from the ÖLFLEX®, ETHERLINE®, UNITRONIC®, and SYLVIN® brands are used, among others.

LAPP also meets the special plant manufacturer’s high expectations in terms of quality and availability: the cables are durable, robust, and reliable. These are properties that are important in reengineering. “What we expect from our partners is technical diligence and absolute reliability,” says Stefan Innerhofer. “And that’s exactly what we’ve been getting from LAPP since day one.”

Partnership-based, sustainable, forward-looking

Last but not least, regineering values the cooperative partnership on an equal footing. From technical advice to the rapid provision of the necessary components, everything runs smoothly, pragmatically, and in a solution-oriented manner. For a growing company with complex projects, this is an important factor for success. “We don’t need long coordination processes, but people who understand our requirements. And at LAPP, that just works,” says Stefan Innerhofer.

This view is mutual, as Markus Schreiber, Account Manager at LAPP, confirms: “We have a close, trusting working relationship with regineering. We know that they have the highest standards of technology and reliability. That’s exactly what motivates us to work as partners on an equal footing.” The partnership shows that when the highest technical quality, trust, and shared values come together, the result is a sustainable connection that has an impact beyond the collaboration itself.