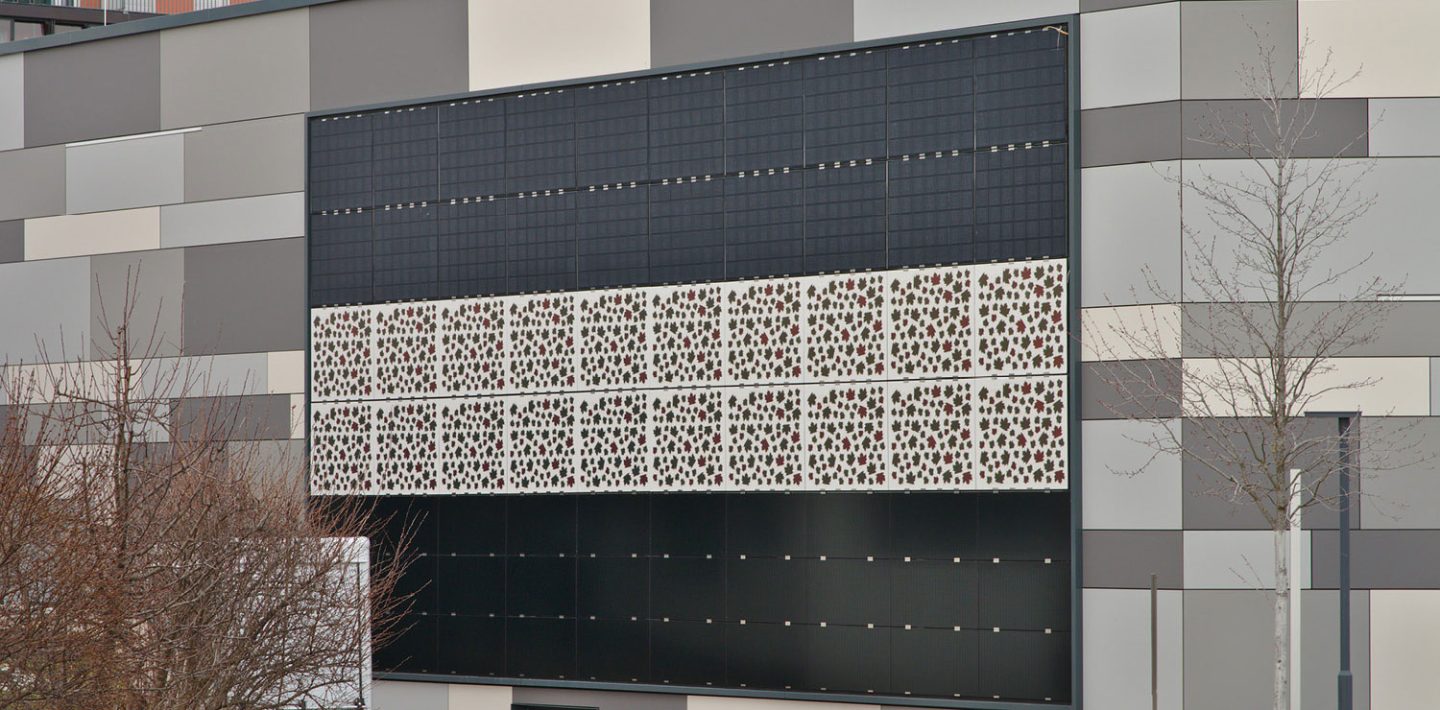

The solar roof obligation is coming – first for commercial buildings, soon also for residential buildings: the first German states want to introduce it this year. Every new building – in some federal states this also applies to car parks – will then have to install a photovoltaic system on the roof and thus make a small contribution to reducing CO2 emissions in the country. But why always “on the roof”? The facades of buildings offer much larger surfaces and are just as suitable for generating electricity – provided they face south. According to the Fraunhofer Institute for Solar Energy Systems in Freiburg, this would allow 1400 gigawatts of photovoltaic capacity to be installed in Germany alone – currently there is only a total of 54 gigawatts. Photovoltaics can be integrated into building elements that, in addition to generating electricity, take on classical functions such as thermal insulation, wind and weather protection. If only they weren’t so unaesthetic. Conventional photovoltaic modules with aluminium frames disfigure every facade, modules made of chic glass or organic materials are expensive. What they all have in common is that hanging installation is rather complex and thus cost-intensive.

The research project “Building Integrated Photovoltaics” (BIPV) broke new ground here. It was funded by the German Federal Ministry for Economic Affairs and Energy – renamed the German Federal Ministry for Economic Affairs and Climate Protection after the change of government – with around two million euros. After starting in January 2017, the project ended in September 2020. The goal of the six partners under the leadership of Fraunhofer ISE was to “develop a prefabricated standard BIPV facade for selected building categories in Germany for the energy-efficient refurbishment of existing buildings and provision of on-site renewable energy”, as the project application states.

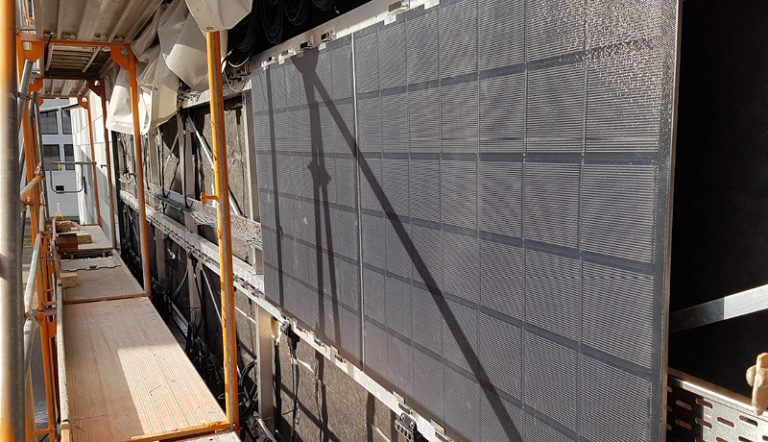

New connector facilitates installation

In one work package, LAPP looked at the connector on the PV modules. Until now, when the modules were hung on the facade, they were wired by hand, basically like a rooftop or ground-mounted system. The world market leader for integrated cable and connection solutions also has corresponding connectors in its product range. The BIPV project is breaking new ground here. The aim is for the connectors, which are permanently installed in the modules, to automatically and permanently connect to their counterpart on the support structure when the installer presses the module into the suspension. There is no need for subsequent wiring, which saves time and avoids errors.

Together with the partners, LAPP defined the requirements for the connector as follows:

- Rated voltage 1500 V DC

- Rated current 30 A

- IP protection class IP 68 (1m/10h)

- Temperature range -40° C – +85° C

- Number of poles 4

- Mating cycles 50

Plug-in connector compensates for tolerances

It was also determined that one half of the connector would be pre-assembled on the solar module and the counterpart on the frame on the facade. The permissible tolerances for connectors are usually a few tenths of a millimetre. Such small tolerances can never be guaranteed when assembling a large facade construction; the thermal expansion alone would exceed these values. The LAPP team therefore decided that the connector half on the façade frame should be floating, i.e. moveable within certain limits, in order to compensate for tolerances.

The result is a connector with a socket that is laminated to the solar panel via a core composite panel. The counterpart on the facade is an angled connector that is attached to the aluminium frame. The complete connector was subjected to testing in the development laboratory and passed all requirements.

However, the first connector designed by the LAPP team was discarded because it no longer fitted the solar module, the frame of which was redesigned during the course of the project. LAPP has a patent for both the first and the second connector. Nevertheless, the second plug will not go into series production either. The reason is that this plug also only fits this one frame and that this frame will probably be modified again for a series product. “There was no system integrator in the project – that was a mistake,” admits Werner Körner, Head of Development and Technology at LAPP, frankly. This gap is now to be closed in another research project.