Complex procurement processes can quickly become an efficiency problem for companies. Item master data must be maintained manually, price lists quickly become outdated, and orders require time-consuming comparisons between online shops and ERP systems. This leads to additional work, error-prone processes and avoidable media breaks. This is exactly where the Open Catalog Interface (OCI) comes in. The digital interface connects a supplier’s online shop directly to the customer’s ERP system. Prices, item information and shopping baskets are transferred at the touch of a button, without any manual double entries. The result is a noticeably simplified purchasing process.

SAB Steuerungs- und Anlagenbau GmbH, based in Nufringen, introduced OCI ten years ago and, in collaboration with LAPP, connected its online shop via this interface. The global market leader for integrated solutions and branded products in the field of cable and connection technology ( ) offers not only high-quality technology but also sophisticated digital services such as the OCI interface, which SAB has been using ever since. And the results are impressive: “Processing large amounts of data used to be a nightmare,” recalls Bruno Bachmann, system administrator at SAB. “Today, up-to-date prices, accurate product information and a fully digital ordering process in the system ensure that we save time, avoid errors and maintain an overview at all times.”

Tailor-made solutions meet manual procurement

SAB develops and manufactures customised solutions in energy distribution, automation and environmental technology. The medium-sized manufacturer of switchgear does not supply off-the-shelf products, but plans and builds each project according to the specific requirements of its customers. The range of services extends from large energy distribution systems for production halls to control systems for sewage treatment plants or water treatment facilities. Its customers include industrial companies as well as major German car manufacturers.

“We see ourselves as a manufacturer to a certain extent,” explains Bruno Bachmann. “Our internal processes must therefore be flexible and precise.” This includes purchasing, which regularly has to procure high-quality components and materials such as connection and control cables in varying quantities for the systems.

Before 2015, this process was still largely manual, which meant that efficiency and accuracy were out of the question. Article master data was managed locally, often based on data records in Datanorm format. These had to be regularly updated, maintained and, in some cases, corrected manually. This was time-consuming and prone to errors. “Some prices were out of date, items were no longer available and the amounts of data were huge,” recalls Mr Bachmann. “I spent entire nights in the server room because imports didn’t go through or we had problems with incorrectly formatted data.”

Real efficiency gains: Entering the world of OCI

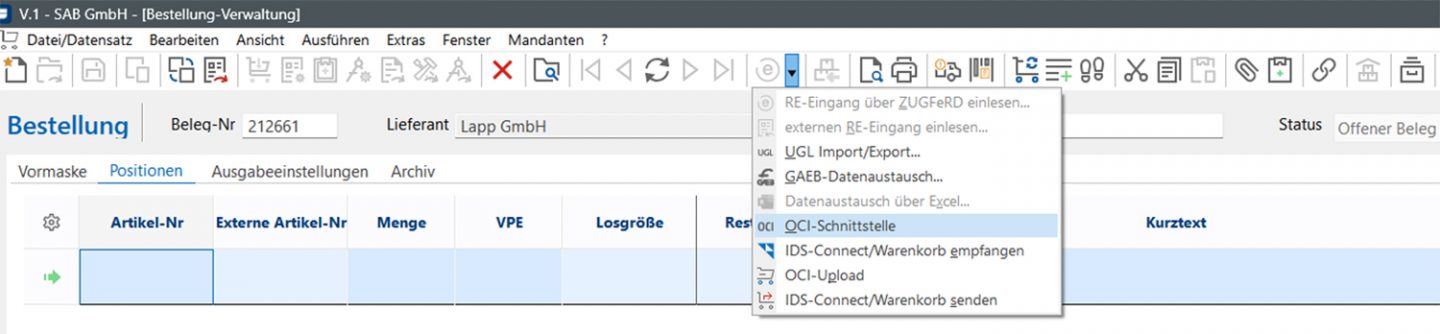

The need for a reliable, automated solution became increasingly apparent. Finally, in 2015, Bruno Bachmann, the manufacturer of the company’s proprietary ERP system “Streit V.1”, drew attention to the advantages of an OCI interface. While searching for suitable partners who supported this interface, he came across LAPP and quickly found a receptive audience there. “After submitting a request to LAPP, we immediately started a field trial,” says Mr Bachmann. Together with LAPP, he coordinated the technical implementation, both sides adapted their systems, and after a short time, the first version of the OCI connection was ready for use.

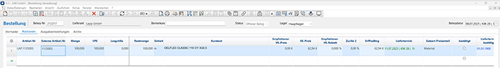

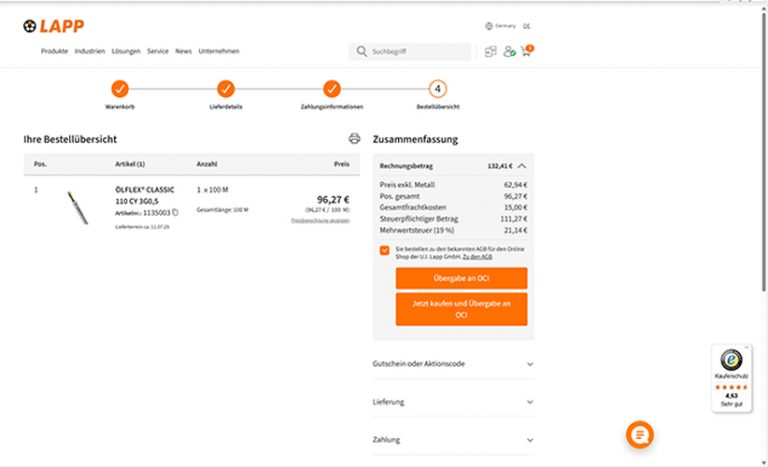

The advantages quickly became apparent: instead of maintaining outdated product data locally, SAB could now access the LAPP online shop directly. There, the purchasing department selected the required items, including daily updated prices and availability, and transferred them to its own ERP system with a single click. Media breaks and manual double entries were now a thing of the past. “This was a real milestone for us,” says Mr Bachmann. “We no longer had to import masses of item data and could be sure that the information from the LAPP system was always up to date and correct.”

Stable connection, continuous improvement

Since the introduction of the OCI interface, SAB and LAPP have enjoyed a close partnership. Technical adjustments, queries or minor operational challenges are resolved quickly and easily. “If we have a question, I send an email and shortly afterwards someone from LAPP gets in touch. The background service runs smoothly,” emphasises Bruno Bachmann.

The switch to LAPP’s new online shop brought further advantages. The modernised platform offers an improved user interface and extended functionality, which can also be used via the OCI interface. For SAB, this means even greater convenience in the ordering process with the same technical stability.

And LAPP is continuously improving the OCI interface. The latest development is that, in addition to the basic sales price, the so-called full metal price of the connection solutions can also be transferred via the OCI interface. The current metal prices and any cutting costs are included in the calculation, so that the most realistic possible quotation can be provided. “The price of copper makes a significant difference, especially for larger cable cross-sections,” explains Mr Bachmann. “If this is taken into account automatically, it saves queries and increases the accuracy of quotations.”

Digital expertise as a factor for efficiency and success

The partnership between SAB and LAPP demonstrates the contribution that digital interfaces can make to efficiency and reliability in industrial procurement. For LAPP, supporting such processes is an important cornerstone in offering its customers added value beyond providing high-quality connection technology. “From a technical point of view, OCI is a standard format. But for it to work smoothly, it requires experience, flexibility and a deep understanding of our customers’ systems,” explains Donovan Gregory, Digital Marketing and E-Commerce Manager at LAPP. “Adherence to the standard ensures stability, compatibility and easy connection, even with many different customers. At the same time, we have the expertise to make adjustments within the framework of the standard so that it fits optimally into the respective individual system landscape.”

Close coordination with customers such as SAB allows technical adjustments to be implemented pragmatically and continuously improved. “This is an important factor for us in ensuring a stable and efficient procurement process,” says Bruno Bachmann. “That’s why we will continue to rely on LAPP’s digital and technological expertise in the future.”