Oil billionaire John D. Rockefeller once described his recipe for success with the following short statement: “Rise early, work hard, strike oil.” On an oil rig in the North Sea off the coast of Norway, the early shift that have just dragged themselves from their beds know exactly what he meant. Nobody here will become a billionaire, although the salary is very lucrative compared to jobs on land. Three weeks’ work back-to-back and then three weeks’ holiday at home – for many people, this is an attractive model. Even when your colleagues start swearing when they open the airlock to the platform and the wind whistles in. The air is dry today, which makes the work more dangerous than usual. This is because plastics gain an electric charge in these conditions which can cause sparks, and no one wants to contemplate what that could mean when oil vapours are involved. Luckily, all the technical equipment is earthed so that the charges are quickly dissipated – even the work clothing and especially the shoes prevent charging. A few weeks ago, colleagues from a specialist Norwegian company for drilling technology were here and installed a new supply cable from LAPP that would also not be charged. Since then, the 500 people on the artificial island have felt a little safer.

Dangerous sparks

Even two objects rubbing together can cause the black gold or its vapours in the air to ignite. We can see just how easily this happens in winter in heated rooms. When shaking hands or grabbing a door handle, a spark flashes into your palm, making you flinch. This phenomenon is particularly spectacular when you pull a jumper made of synthetic material over your hair, leading to a full-on light show. The voltages involved here are surprisingly high. We only notice charges of over 2,000 volts. When walking over a carpet in a heated room, your skin can have a charge of up to 30,000 volts. This is unpleasant but not dangerous – unless there are explosive substances nearby such as oil, gas, but also wood and flour dust. In these situations an electrostatic discharge can lead to a catastrophe, as was the case in the Hindenburg disaster in 1937, when a spark from the airship’s electrostatically charged shell caused the hydrogen gas inside to explode.

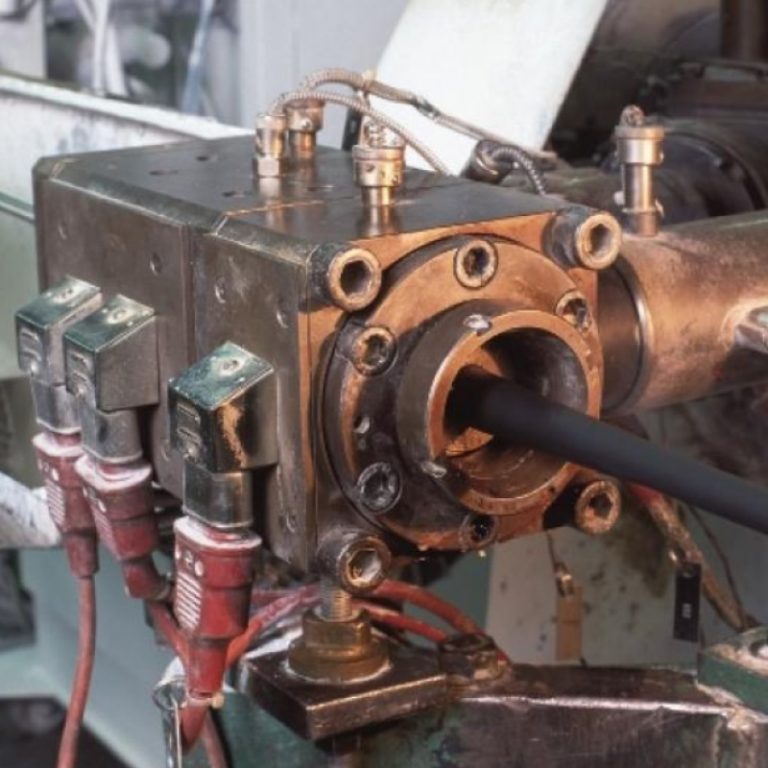

Cables also present a potential hazard. Electrostatic charges can build up in the sheath due to friction and discharge suddenly. The charge carriers collect on cables or other low-conductivity objects mostly as a result of frictional electricity. This depends on the discharge capacity, which should be as high as possible so that the charge carriers on the surface of the object – in this case the cable sheath – are discharged to the air as quickly as possible. The LAPP supply cable, which is used on oil rigs belonging to the Norwegian manufacturer Aker Solutions, is therefore equipped with an anti-static sheath – it is the first of its kind in the world. It is not a cable in the strictest sense, but more of a sheath containing an entire bundle of different cables. Overall, this bundle is 18 centimetres thick and is custom made, so it is not a standard product in the range.

Secret ingredient

The secret of this anti-static cable can be found in its sheath. It is made from a plastic with a special additive that increases conductivity. Although you would think that this would jeopardise the electrical insulation, this fear is unfounded. The conductor is always insulated by the insulator that surrounds the conductor. The external sheath of a cable has no insulating function. Instead, it provides mechanical protection against oil, chemicals or in this case drilling mud, as well as against bending, torsion and friction. The exact composition of this additive is top secret, especially the complex process of adding the additive to the plastic in the correct quantity and mixture. Developing the cable was especially complex, as in addition to fulfilling the aforementioned requirements for preventing ignition hazards, the cable also had to meet the specifications of NEK 606. This is an exceptionally strict standard that regulates the properties of marine cables and protection against drilling mud. The real innovation was being able to combine both of these properties.

Extract from our catalogResistant to oil and drilling fluids |

||

The new cable insulation makes life considerably easier for the designers of the platforms because there is no need for complex safety precautions. This also applies to other branches of industry where there is a risk of explosion, such as in the wood processing industry, where wood dust poses a danger, or when processing flour in the food industry.

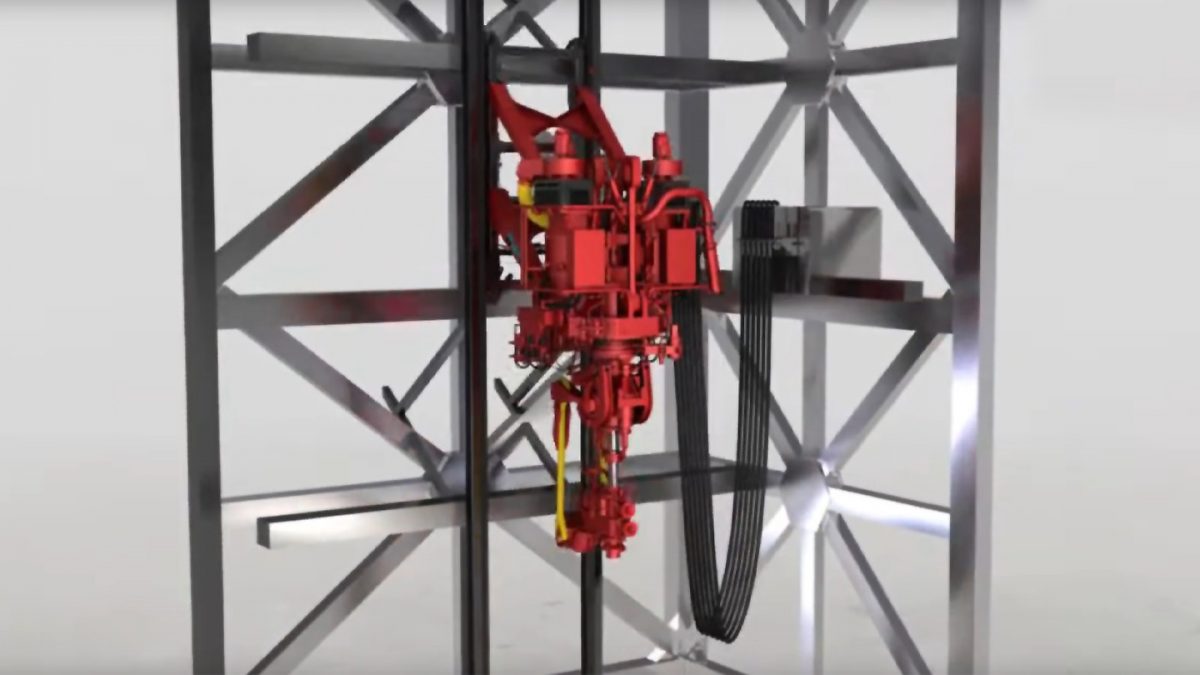

Video: © LAPP Norway (Miltronic) – specially developed cables for drag chains for oil rigs and offshore