ETHERLINE® GUARD is a stationary monitoring device that evaluates the current performance of a data cable and indicates it as a percentage. This is based on data that is determined from the physical properties of the data transmission via a sensor system. The real-time status display makes it possible to recognise the wear limit of a line and to plan the optimal replacement time in advance. This is particularly interesting for data cables at risk of failure in positively driven industrial applications with fast movements and strong bending loads. In many industries, such cables are used in the last few metres or at the process level of an application and are thus often part of drag chains or cable guides, such as robot arms.

ETHERLINE® GUARD – Product Information

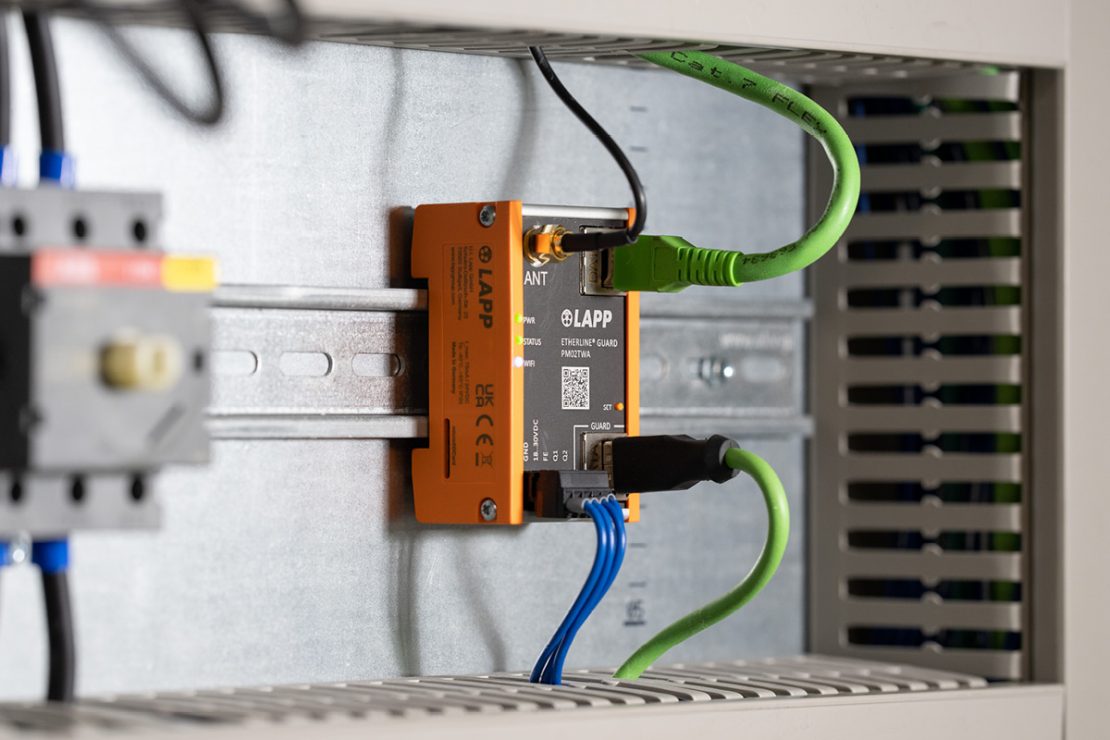

- Compact size: 49mm wide, 76.5mm high and 36mm deep

- The device is operated with 24 V DC, is designed for a temperature range of -40 °C to +75 °C and is vibration and shock resistant according to DIN EN 60529.

- LAPP recommends the ETHERLINE® GUARD especially for data cables according to the transmission standard 100BASE-TX (up to 100 Mbit/s) according to IEEE 802.3, but also for EtherCAT, EtherNET/IP and 2-pair PROFINET applications, such as the ETHERLINE® TORSION Cat.5 or the ETHERLINE® PN Cat.5 FD.

Stationary monitoring device for use in the control cabinet

The ETHERLINE® GUARD is particularly space-saving, compact and is plugged into a data line node between the cable to be monitored and the control side. An easy-to-use SET button is provided for calling up various functions, such as teach-in, or activating the access point. ETHERLINE® GUARD has a GUARD/data port for the data cable to be monitored with an RJ45 connector, which leads from the critical application to the device, and a DATA port for the data cable with an RJ45 connector, which leads from the device to the controller. By connecting a third data cable to the LAN socket (variant PM03T) or by using the antenna connection for WiFi (variant PM02TWA), the maintenance data can be transmitted to a higher-level control. Both variants can be configured for cloud communication with MQTT.

Video: © LAPP: ETHERLINE® GUARD – Cable monitoring made by LAPP

Simple overview of the performance of a data cable

There are three centrally arranged multi-coloured diagnostic LEDs on the unit: PWR for operational readiness, STATUS for the status of the data cable to be monitored and COM for Connect (LAN version) or WiFi (WiFi version). The developers of LAPP have deliberately provided only simple diagnostic and setting options on the unit. Additional settings are also possible. The setup is simple – no IT expert knowledge is required. It takes only a few minutes with an automated and self-learning parameterisation (“teach-in”). Retrofitting into the existing network structure is also possible at any time. Thanks to the two variants and a wide range of diverse connection options, the user can decide how the required status information is to be transmitted to the higher process level. On the unit itself, the cable status can be quickly recognised by one of the LEDs visible all around. The type of display is based on a traffic light system. It lights up permanently green when the cable is functioning perfectly and is within the specifications. If the web interface reports the yellow area or the STATUS LED flashes red, the first signs of wear have already occurred, and action is required. When ETHERLINE® GUARD informs about a deterioration in the condition of the read-out sensor data can be individually set between 99 percent and 21 percent via the alarm trigger threshold. The factory setting is 80 percent.

ETHERLINE® GUARD is particularly suitable for data cables that are constantly exposed to “stress”: These are movements with high speeds and accelerations, alternating motion sequences, rotations with axially very high twisting angles, fast cycle times and small bending radii. The device is also used in critical processes where high to extremely high downtime costs or even personal injury would occur in the event of a standstill. With the Smart Guard, LAPP enables customers to take another step on the way to the Smart Factory.

Information about the Author

Dipl.-Ing. Stefan Hilsenbeck gained several years of experience in the field of industrial sensor technology and automation after studying optoelectronic laser technology at Aalen University. At LAPP, in his current position Senior Engineer Advanced Technology, he significantly advances relevant technology topics such as EMC and predictive maintenance.

Dipl.-Ing. Stefan Hilsenbeck gained several years of experience in the field of industrial sensor technology and automation after studying optoelectronic laser technology at Aalen University. At LAPP, in his current position Senior Engineer Advanced Technology, he significantly advances relevant technology topics such as EMC and predictive maintenance.