When it comes to the term gold rush, many people think of the huge California gold rush that occurred between 1848 and 1854, where hundreds of thousands of people sought their luck and only a few found it. In all likelihood, nobody remembers a gold rush in the Apuseni Mountains, but the region is closer than people think. They are an almost circular mountain range measuring 150 kilometres in diameter in the West Carpathian Mountains in western Romania. The Apuseni Mountains comprise one of the most abundant gold regions in Europe, where even the Romans mined the noble metal. There are still large deposits to this day, but they are rarely exploited.

A young company aims to revive the old tradition, and its name says it all: Goldrush Mining. The start-up is committed to mining gold using state-of-the-art methods without damaging the environment, i.e. without the use of chemicals. Gold extraction no longer has anything to do with the miserable working conditions of the pioneers, who had to wash the nuggets out of the river water using just a sieve. Instead, large machines will extract the small gold particles from the riverbeds and separate them from sand and gravel. The new technology also aims to avoid the severe environmental damage caused by cyanide alkalisation or the use of mercury, which is common in other regions of the world. An international team of experts has developed a new generation of machines for this young company.

Gravity instead of chemicals

The process will be highly automated. It is based solely on the fact that the heavy gold is separated from lighter components by gravity or in filters, i.e. purely mechanically. The floating material in the river is extracted from the shore area using submersible pumps on hydraulic excavators and cleaned in a washing system. The pre-washed ore passes through an inclined vibration plate that separates sand and gravel and guides it back into the river. A sluice box captures the gold clumps and finer components are placed in a separator with vibrating polyurethane sieves. The next step is a centrifuge. The finest dust is then filtered on a vibrating table that collects gold measuring just micrometres.

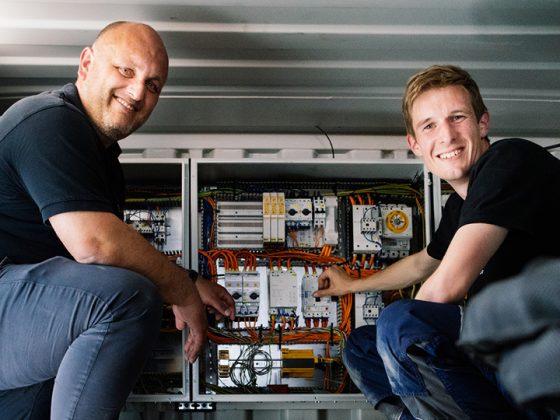

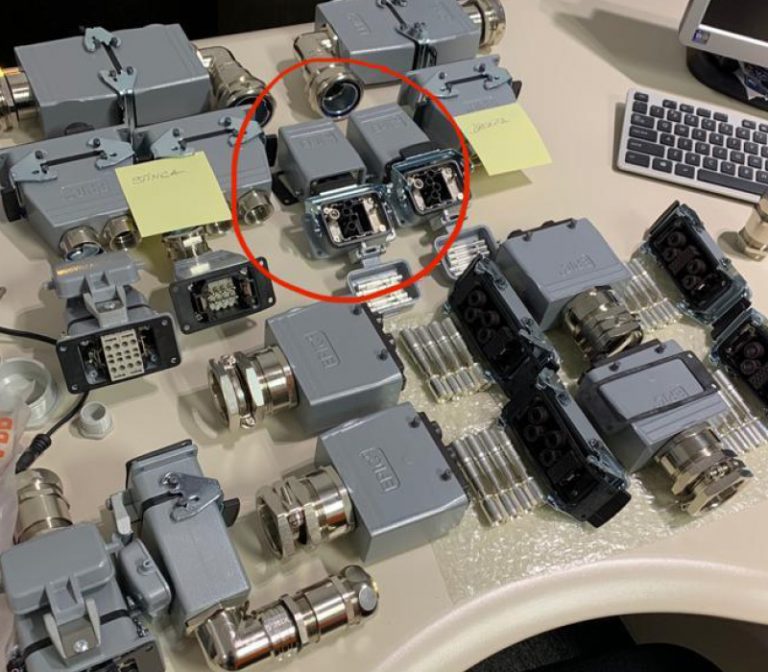

The first of the 15 planned machines is currently under construction. It is a prototype that works under the most adverse conditions: cold, heat, dust and vibrations. The electrical connection systems also have to withstand this. These come from LAPP: the machine contains hundreds of metres of power and control cables, as well as data cables, modular connectors, cable glands, protective conduits and labels.

The collaboration began with an enquiry from Goldrush Mining to LAPP for liquid-tight metal pipes in which cables were to be installed. Alexandru Riza, Business Developer Manager at LAPP in Romania, dug deeper and found out that Goldrush Mining wants to build giant gold extraction plants, which are transported on the road in five parts. The potential customer needed a complete system for the electrical connections for power, signals and data. Riza was told that the gold sorting plant needed to “devour” 500 tonnes of gravel and sand in one hour.

Patience and diplomacy

Then everything became complicated. Due to the pandemic, many telephone calls, e-mails and pictures were needed to assess the exact requirements. “Goldrush Mining was a challenging customer. If something was unclear, we always called on the phone, often even late at night if it was urgent,” said Riza. “That required a lot of patience and diplomacy.” Riza worked out all the technical solutions together with Product Manager Dan Ciortea. Based on the nominal current or the nominal output of the consumers or the type of signals, they determined the cable cross-section and type of connector, the housing, the cable gland and further details. To be as flexible as possible, they mainly opted for modular connectors. For each of these connections, it was necessary to check whether the liquid-tight metal pipes were large enough to accommodate all cables and whether the thread dimensions matched the tube glands and the housing.

“It was a great project that we supported from scratch and where we were able to implement our full array of technical skills,” said Dan Ciortea. It was once again shown that LAPP can stand out from its competitors with its complete system solutions. “The engineers at Goldrush Mining are very satisfied with LAPP because we gave them valuable technical support with regard to engineering and selecting the connection systems,” said Alexandru Riza. “In the meantime, we have built up a very good personal relationship of trust.”

Video: © Goldrush Mining