(© Icelandic Meteorological Office)

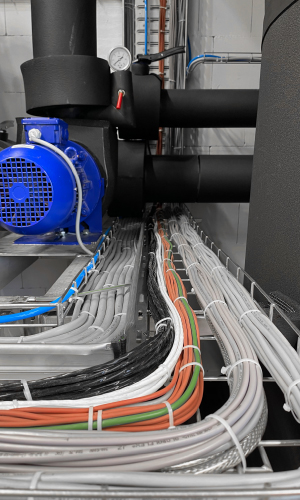

If the flow of data or energy fails, operations quickly come to a standstill – no machine or system can function without connection solutions. However, the technologies are not only used in familiar operating environments and production halls, but also in atypical areas of application. There they have to withstand humidity, heat, cold, pressure, vibration, fiery sparks or radiation for years on end. Failure can have serious consequences, from production stoppages to safety risks.

LAPP therefore offers a broad portfolio of connection solutions that have been specially designed for use in extreme conditions – and the global market leader for integrated solutions and branded products in the field of cable and connection technology is constantly developing these further. Hubertus Breier, Chief Technology and Innovation Officer at LAPP, explains: “Extreme conditions require exceptional solutions. At LAPP, we focus on innovation, quality and robustness to ensure that our products function reliably for a long time, even under the most demanding challenges. This gives our customers peace of mind and is often one of the reasons why they choose LAPP as their partner.”

The Stuttgart-based company has demonstrated its expertise in a wide range of applications. In eight scenarios, LAPP demonstrates the resilience of its connection solutions – be it in temperature fluctuations, chemical and mechanical stress or in deep water.

1. Underwater – Resistance in Wet Depths

Pipes that are used under water must not only be watertight, but also withstand high pressure and aggressive substances such as sea salt. For these conditions, LAPP offers special customised cables that function smoothly even under extreme conditions. One example of this is the European research project FOCUS, which is researching the early detection of seaquakes. The aim of the project is to prevent disasters similar to the 2004 tsunami, in which 230,000 people lost their lives. For this project, LAPP developed an underwater expansion cable that can withstand the enormous pressure at depths of up to 2,000 metres while ensuring interference-free data transmission.

Customised connection solutions from LAPP are also used in aquaculture for fish farming. The Norwegian company Harbor AS offers salmon farms a preventive solution that keeps parasites such as salmon lice away. An electrode cable stretches a kind of “fence” that creates an electromagnetic field around the farm animals – which does not disturb the salmon but prevents the parasites from attaching themselves to the animals. For this purpose, LAPP developed a robust, corrosion-resistant cable that ensures reliable operation in the long term. Due to the increasing demand for connection solutions in aquaculture, LAPP is expanding its portfolio with the ÖLFLEX® AQUA 510 P. The new connection and control cable is especially suitable for use in rough waters such as oceans. It is particularly robust and ozone-resistant and ensures a reliable power supply for automatic feeders, aeration systems and other systems in controlled water basins and net cages.

2. Icy Cold – Works even at sub-zero Temperatures

Whether in frosty Siberia or the icy Arctic – connection solutions must function smoothly even in temperatures well below zero. One major challenge is the transport of temperature-sensitive pharmaceuticals – an extreme example of this was BioNTech’s Covid-19 vaccine, which had to be stored at extremely low temperatures and transported by ship and aeroplane. L&R Kältetechnik, a specialist in refrigeration systems, developed a solution for this with cables from LAPP. In the refrigerated containers, the cables, including ÖLFLEX® Classic 110, have to withstand both extreme cold of up to minus 100 °C and heat of up to 100 °C plus. With such pharmaceuticals, any failure in the electronics can jeopardise human lives, which is why L&R Kältetechnik plays it safe with cables from LAPP.

3. Fire Protection – Safety in glowing Heat

Fire protection plays an essential role in many areas of life, as people’s well-being often depends on it. This is also the case in high-tech medical applications, such as tumour therapy with synchrotrons at the Italian National Centre for Oncological Hadron Therapy. Here, cables not only have to withstand high levels of electromagnetic radiation, they also have to be fire-resistant. LAPP supplied 1.6 kilometres of UNITRONIC® RE-2Y(ST)Yv PiMF data cable, which is CPR-classified and therefore meets the highest fire protection standards.

Fire-resistant cables are also indispensable components in industrial areas such as foundries, steelworks and the chemical industry. LAPP has designed the new heat-resistant ÖLFLEX® HEAT 700 SC cable, which can withstand continuous temperatures of up to 700 °C, to meet these requirements. With nickel-plated copper conductors for optimised electrical conductivity and multi-layer glass fibre insulation, it protects against heat and fires.

4. Extreme Heights – Work safely even when flying at Heights

The conditions on the upper floors of a skyscraper are anything but ordinary: strong winds, temperature fluctuations and intense UV radiation pose challenges for the use of connection solutions at great heights. To ensure the reliable operation of its façade access systems even under these weather conditions at Manntech, a provider of façade access solutions, relies on high-quality connection solutions from LAPP. These ensure that the façade access systems continue to function without failure in the long term. LAPP supplied weather-resistant and durable cables, including ÖLFLEX®, UNITRONIC® and HITRONIC®, which prove their reliability even at dizzying heights.

5. Mechanical Stress – Withstand constant Movement and Pressure

In sectors such as industry and vehicle construction, cables are often exposed to high mechanical stress due to vibration or deformation. In buses and coaches, for example, cables have to withstand countless bending cycles without breaking. The Czech bus manufacturer IVECO uses ETHERLINE® and UNITRONIC® data cables from LAPP for its bus communication system. These cables are particularly flexible and therefore fulfil all the safety requirements needed for passenger transport.

The load is even more extreme in cement works, where systems are exposed to high temperatures, aggressive dust and strong vibrations. For one of the largest cement works in Togo, the Polish company AIUT developed a chain guide for a forklift truck and relied on LAPP’s expertise. For this project, the Stuttgart-based family business supplied robust connection and control cables from the ÖLFLEX® portfolio and HITRONIC® fibre optic cables, which are ideal for continuous operation in the cement plant thanks to their robustness, flexibility and heat resistance. After successfully passing stringent tests, these solutions guarantee the operational safety of the systems.

6. vacuum – working in a vacuum

In a vacuum, which is created under special conditions during electron beam welding, cables must be extremely robust and gas-tight. As air immediately slows down the electron beams, cables must not emit any particles – even the smallest particles could disrupt the welding process. This is why Steigerwald Strahltechnik (SST) relies on the reliability of LAPP for its electron beam welding machines. These welding machines enable high-precision welding in a vacuum and are extremely durable.

LAPP’s high-quality and durable connection solutions are a key factor in this durability. In addition to the technical cable design, the material composition also plays an important role: LAPP uses specially developed plastic mixtures that do not become brittle or outgas even in vacuum environments.

7. Radiation – Resistance to invisible Dangers

Intense radiation, such as that generated by UV light or other types of electromagnetic radiation, can severely damage connection solutions. This is particularly problematic in environments with strong ultraviolet (UVC) radiation, which is often used in air purification or disinfection systems. This radiation causes plastic coatings to age more quickly and jeopardises the reliability of connection solutions.

In a specially developed test procedure, LAPP exposed various cable and wire materials to intensive UVC radiation and achieved clear results: Many standard materials did not withstand the intensive radiation, while all cable types from LAPP’s ROBUST series successfully passed the test. Thanks to their special material composition, the sheaths of these pipes are particularly resistant to UVC radiation and therefore offer a reliable solution for disinfection systems. LAPP experts are continuously working on optimising other products in the portfolio for use under UVC radiation.

Whether under water, in icy cold, under intense radiation or under constant mechanical stress – the applications presented are just a few selected examples of how versatile and resilient connection technology must be. For every challenge, no matter how extreme, LAPP develops specialised solutions that permanently withstand the respective requirements. This opens up new possibilities for users and the limits of what is possible become the starting point for progress.