In simple terms, Veena Shankar carries out audits. She does this in all production plants, Sales offices and LAPP Harnessing Solutions units at LAPP’s subsidiaries. More specifically, she provides some insight into processes and uncovers gaps in quality or transparency – from documentation to compliance with applicable national law through standards in production and customer service. “This results in a thorough review of the company and reveals both weaknesses and strengths,” the audit expert explains.

At LAPP, strict sets of rules apply for production, dealing with customers and suppliers documenting the processes and their development. LAPP has a specific audit checklist that needs to be complied with starting from Quality management systems and down to all the functions including shop floors. After the relevant audit checklists have been checked, the audit is winded up with a closing meeting with all the process owners and the top management there by handling over the audit results. Everything is put through its paces to ensure that the global quality standard is met. For example, cable plants in the Czech Republic, Sweden and France have already undergone a complex quality audit which was audited by Veena Shankar in the past, with India recently taking part: “Our plant has achieved first place in the areas of production and LAPP Harnessing Solutions and second place in Sales, after a tedious audit done by Head of Global Quality, Georg Mittnacht and Global Quality Manager Amela Bräuchle”, reports Veena Shankar proudly. “The ranking creates a good incentive so that we do not lose sight of the quality demands and always put ourselves to the test. This is the only way we can deliver on our quality promise at a global level.“

A woman? In production? “This happens in India too!”

“Quality assurance is my passion. We have already reached several milestones for LAPP,” explains Veena Shankar. She was able to demonstrate her first personal success within a few days of starting her career in the production shop floor way back in Bangalore in 2011. She was the only woman working there and was eyed critically – only 24 per cent of women have a paid career in India at all. The female engineer rolled up her sleeves and acted as a motivation for her male colleagues. Today, they form a good team and Veena is convinced she was able to bring about change in the way they thought.

“Quality assurance is my passion. We have already reached several milestones for LAPP,” explains Veena Shankar. She was able to demonstrate her first personal success within a few days of starting her career in the production shop floor way back in Bangalore in 2011. She was the only woman working there and was eyed critically – only 24 per cent of women have a paid career in India at all. The female engineer rolled up her sleeves and acted as a motivation for her male colleagues. Today, they form a good team and Veena is convinced she was able to bring about change in the way they thought.

There are only a few women in cable production in India. The majority work in administration. The Managing Director of the cable plant in Bangalore, Gary Bateman, is supporting the effort to increase diversity. “There needs to be greater protection for women In India. For safety reasons, it is difficult to recruit women to work in all three shifts,” said Shankar. The Indian POSH Act (Protection of Women from Sexual Harassment) was passed in 2013. But a law is far from being a reality. The quality manager is therefore delighted that the management is working on increasing diversity and protecting women.

Experience in quality and culture around the globe

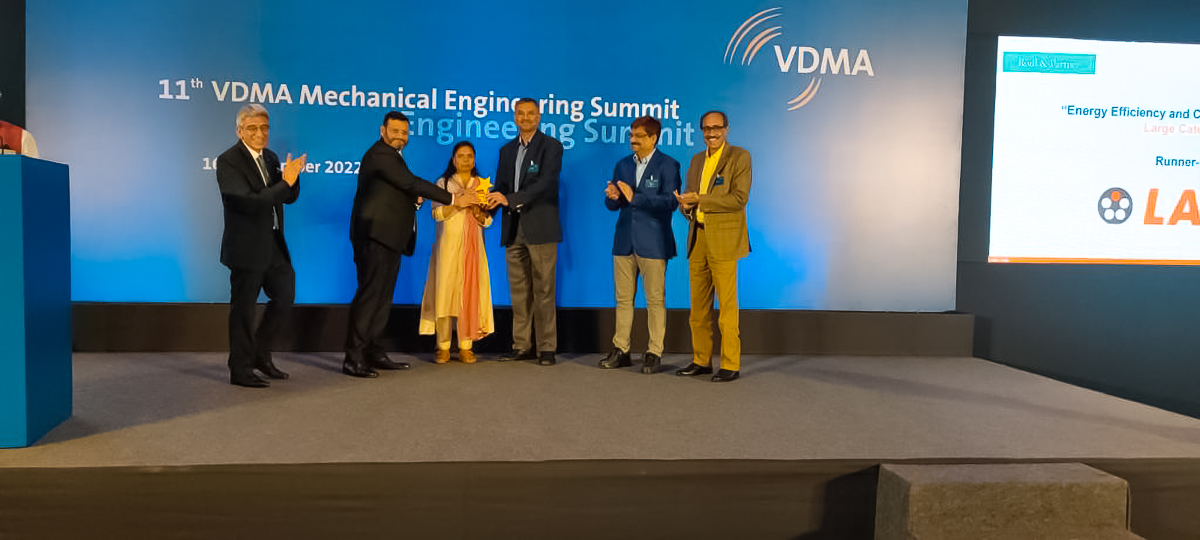

Veena Shankar loves cultural exchange. Her trips to other countries inspire her. The highest number of audits until date was carried out at LAPP’s subsidiaries in 2022 – and she also worked at Lapp Holding SE in Stuttgart for two years. Despite language barriers and cultural differences, she quickly found herself at ease with the team in Stuttgart. The ambitious Indian woman has precise ideas about what the future will bring: “ONE LAPP has huge potential. We can challenge ourselves and our quality again and again. I hope that we can continue this passion and master the future, unpredictable as it is in many respects, with bravado.“ She herself is working on her Master’s degree in Business and various auditing licences. Her perseverance comes from her passion for her work. “It’s important to me that I have a focus in life – everybody needs a passion they can use to actively shape their tomorrow,” she concludes by way of final advice.