When Joris Ploegmakers, Head of Business Development at U.I. Lapp GmbH, speaks about tailored system solutions, he also likes to mention the following story about Tsar Peter the Great: since the Russians had no shipbuilding expertise at the time, the Tsar travelled to Amsterdam at the end of the 17th century to personally learn the craft of shipbuilding incognito as a carpenter there.

What excites Joris Ploegmakers about this story is the impressive approach of the Tsar: faced with a new challenge, he wanted to personally gain as much knowledge as possible about the special requirements of ships on site. “This curiosity and enthusiasm for a project is also important when dealing with customers. The aim is to find out as much about the customer and their special requirements as possible. This is the only way to develop tailored connection solutions for customers. That is the secret of a good partnership,” says Joris Ploegmakers.

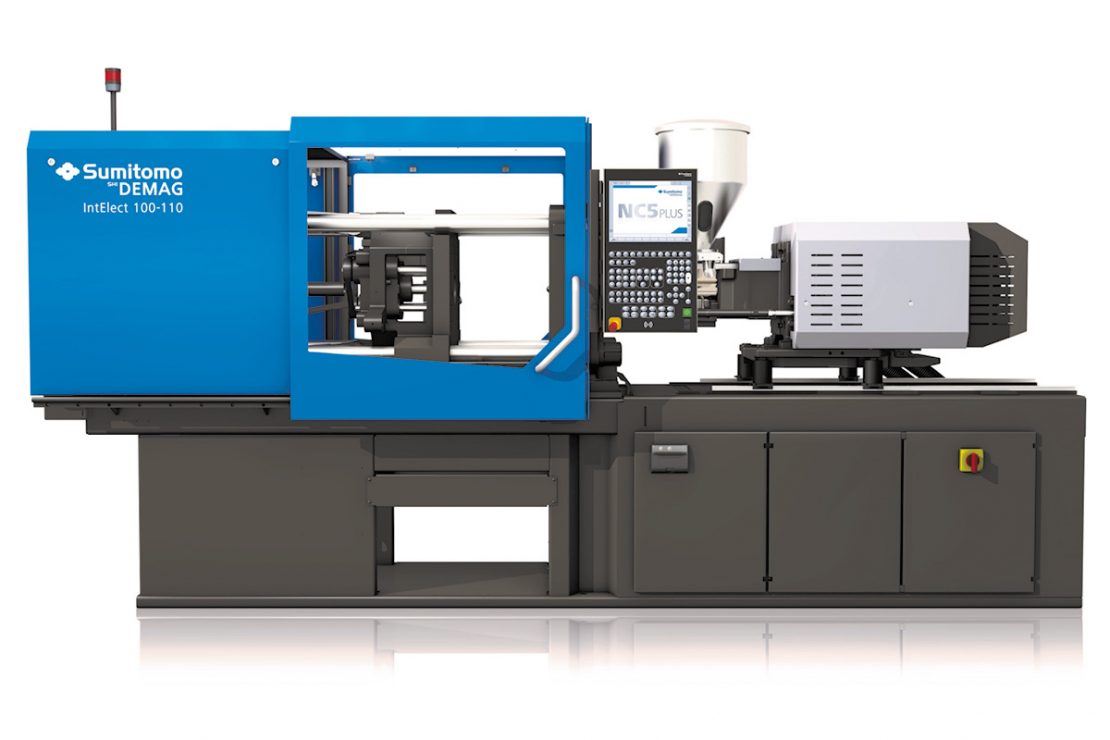

A good example of this is the collaboration with Sumitomo (SHI) Demag Plastics Machinery GmbH in Schwaig near Nuremberg. LAPP takes over the complete assembly of the cable sets for different machine parts for the fully electric injection moulding machine of the IntElect series.

Initially, LAPP supplied Sumitomo with just cables and components. The assembly was organised by Sumitomo itself. A turning point came in 2017, when Sumitomo decided to double the number of injection moulding machines produced per year for the new generation of the IntElect series. The company therefore sought a partner who was able to handle the complete assembly of the individual components for various machine sizes so that the Sumitomo team could concentrate on their core strengths. They wanted a partner to check the cable sets in batch size 1 and deliver them just in time.

An enormous amount of coordination work had to be carried out before the order was finally cut and dried. Numerous technical drawings were exchanged and samples created.

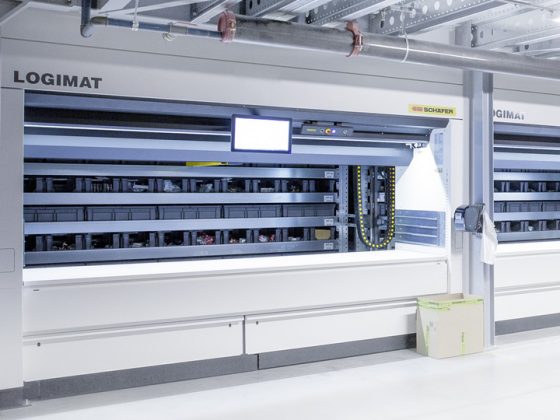

In addition, many of the processes that Sumitomo had carried out independently over the past 20 years did not have one-to-one documentation. “That is why our colleagues visited Sumitomo very often to hold in-depth discussions about the exact requirements with the engineers and the production team,” reports Joris Ploegmakers and adds: “The prerequisite was open and honest communication and, above all, trust.” Every detail behind the creation of a transparent supply chain was also fully thought out. LAPP now makes deliveries to Sumitomo every day, and the time between placing an order and delivery is just 48 hours.

“The effort involved in organising and coordinating this type of outsourcing projects is often underestimated. You need to invest a lot of time, especially at the beginning, to get everything right,” says Joris Ploegmakers. LAPP has even developed its own programme for Sumitomo, which can use the parts list to clearly identify the machine size needed and the country to which the machine is headed. The effort has paid off. These days, the customer just needs to report the type of machine and the LAPP team knows right away which assembled cable sets are required.

LAPP has been standardising and collecting system solutions such as those for Sumitomo under the name LAPP Harnessing Solutions for a few years now. The major advantage, particularly for global customers, is that unlike other suppliers, LAPP is set up all over the world with sites in Europe, Asia and America, and offers global quality standards with regard to engineering, consulting and production expertise.

Joris Ploegmakers: “We are increasingly seeing ourselves as a development partner because we have the expertise for tailored connection solutions and can develop customised solutions with customers as required.”