Amateurs talk about tactics, professionals talk about logistics. There’s a lot of truth in this statement – at least logistics experts think so. But it’s true: “Anyone who doesn’t have control of their logistics and is unable to supply their customers with goods will not survive in the long term”, predicts Boris Katic, COO for the LA EMEA region at LAPP. Customers expect suppliers of investment goods to behave like a kind of Amazon. You order online and the courier rings the bell the next day. Delivery capability is playing an increasingly important role for customers. This is demonstrated by surveys that LAPP regularly conducts, most recently with 500 customers throughout Europe. Regardless of who you ask, the issue of logistics is always in the top 5.

There are several trends in logistics that will have significant effects on companies. Here are the five almost important trends:

Speed is (not) everything

LAPP advertises its ability to get many of its standard products to the customer within 24 hours in many areas of the world. But what is becoming increasingly clear is that it’s not actually about the 24 hours, it’s about finding the “right” delivery time to meet customer requirements. This differs considerably in the different sales channels. An example: LAPP supplied all the cables for the innovative wind farm in Gaildorf, near Schwäbisch Gmünd. The order was placed months before installation, so LAPP knew well in advance which cables had to be supplied. So everything was really relaxed, right? Anything but, as the Max Bögl construction company expected the cables to be available on the construction site at exactly the right moment. More and more customers are demanding just-in-time or even just-in-sequence delivery.

Different sales channels need different logistics

With its new logistics strategy, LAPP is using a segmented supply chain. For its easier to plan project business, for wind power plants for example, the company is supplying products from the new logistics centre in Poland. The logistics and service centre in Ludwigsburg, on the other hand, is highly automated and specialises in standard items and customer-specific solutions. The new logistics centre in Hanover also came on stream recently. It is a kind of hybrid warehouse from where LAPP handles both project and component business.

Logistics needs to look into the future

Why is Amazon so fast? One of the secrets is that the commercial giant always has almost all products in stock, thanks to sophisticated forecasting methods based on self-learning algorithms. LAPP also uses forecasts. Sales prepares a forecast for the coming months and the goods are pre-produced or pre-ordered from suppliers, sometimes even before the customer even gives the order to LAPP. The forecasts’ hit rate of 70 percent is sufficiently high that it is still worthwhile if a prediction is slightly off the mark. “The delivery service at LAPP achieves a very high mark of 98 percent”, says Boris Katic. “This means that we can satisfy almost all orders directly from stock.”

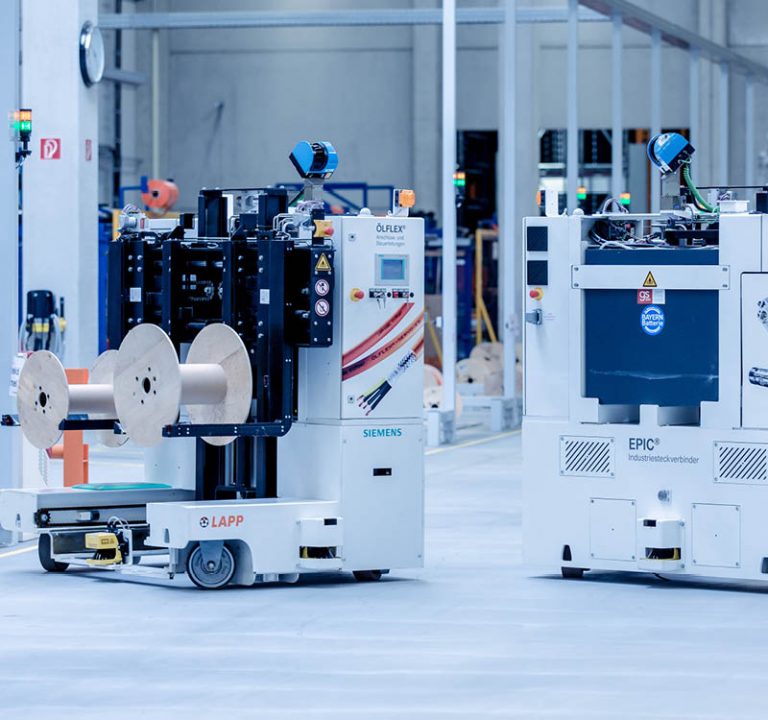

Suppliers and customers exchanging more data

If a customer orders a cable from LAPP, this order passes through the SAP system into the Siemens control system at the warehouse in Ludwigsburg, where the product ordered is automatically collected from the shelf and taken for packaging. This can only be done if all the systems can talk to each other over open interfaces. The trend is that more and more retailers allow LAPP to access their data and systems. This enables LAPP to see when a product is ordered. If stocks fall below a critical limit in the warehouse, LAPP automatically sends a replenishment order without the dealer having to act.

Logistics becoming more sustainable

Many products in daily use travel thousands or even tens of thousands of kilometres all over the world before they end up in our supermarket. This results in high resource consumption and a large CO2 footprint. LAPP does everything in its power to make transport routes as short as possible. A cable produced in Italy and intended for a customer in Italy is delivered directly from the factory. LAPP currently has supply partnerships with 19 suppliers. For example, the same truck drives the cables from a supplier to LAPP’s customers and their own customers. These measures have enabled LAPP to increase truck utilisation from 60 to 80 percent and shorten transport routes by a third.

According to Boris Katic, this overall package of more innovative and customer focused logistics is paying off: “During the Coronavirus crisis, we have gained market share thanks solely to our superior delivery capability.”

Download brochure LAPP Logistics

Video: © LAPP Logistics – There for you worldwide